We are glad to present you our new complete line for the ATM yogurt packing.

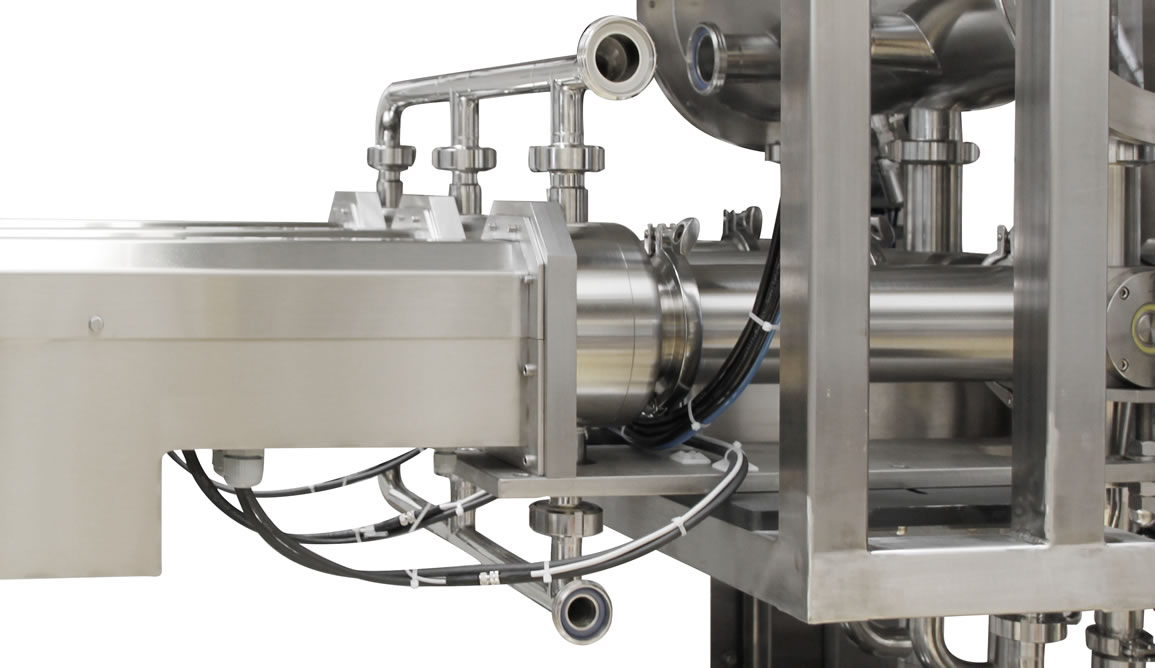

Managed by only one software for all countless functions, among that sticks out the management of the saning CIP phases, the Polaris Double “Yogurt” is provided by multiform tray denester, UV lamps, HEPA filters, yogurt special volumetric brushless dosers, double MAP unit and high speed lid applier.

The end-line foresees, as usually, a practical one-line tray aligner that manages potentials metal detectors, weight control or pricelabel weight.

Proud of a 36/42 trays /minute in MAP productivity, 48/54 in vacuum sealing only and 66/72 in sealing only, the Polaris Double “Yogurt” is one of the faster and most flexible among its class.

We underline the not less important advantage to work even at single step in all the various areas of the machine , from denester to the lid applier.