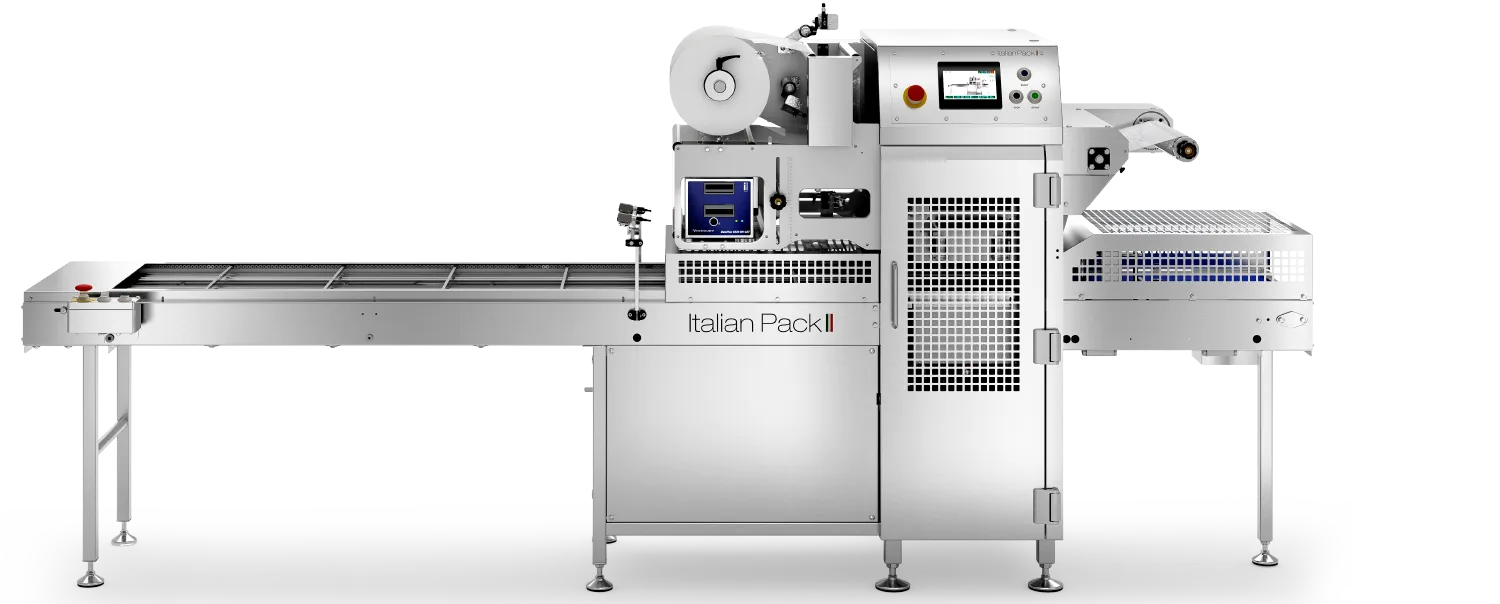

Technologies

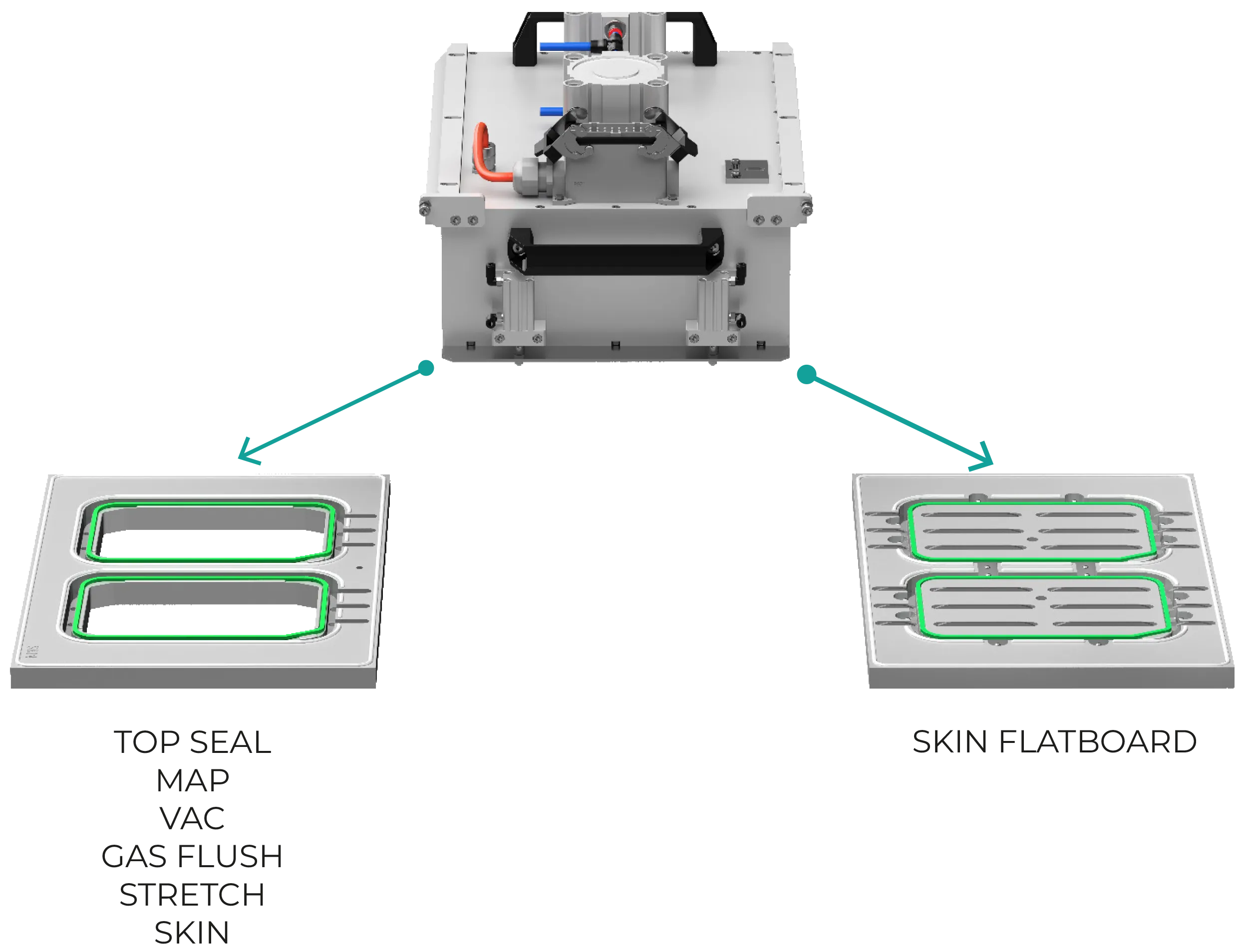

1 Tool - 7 Technologies

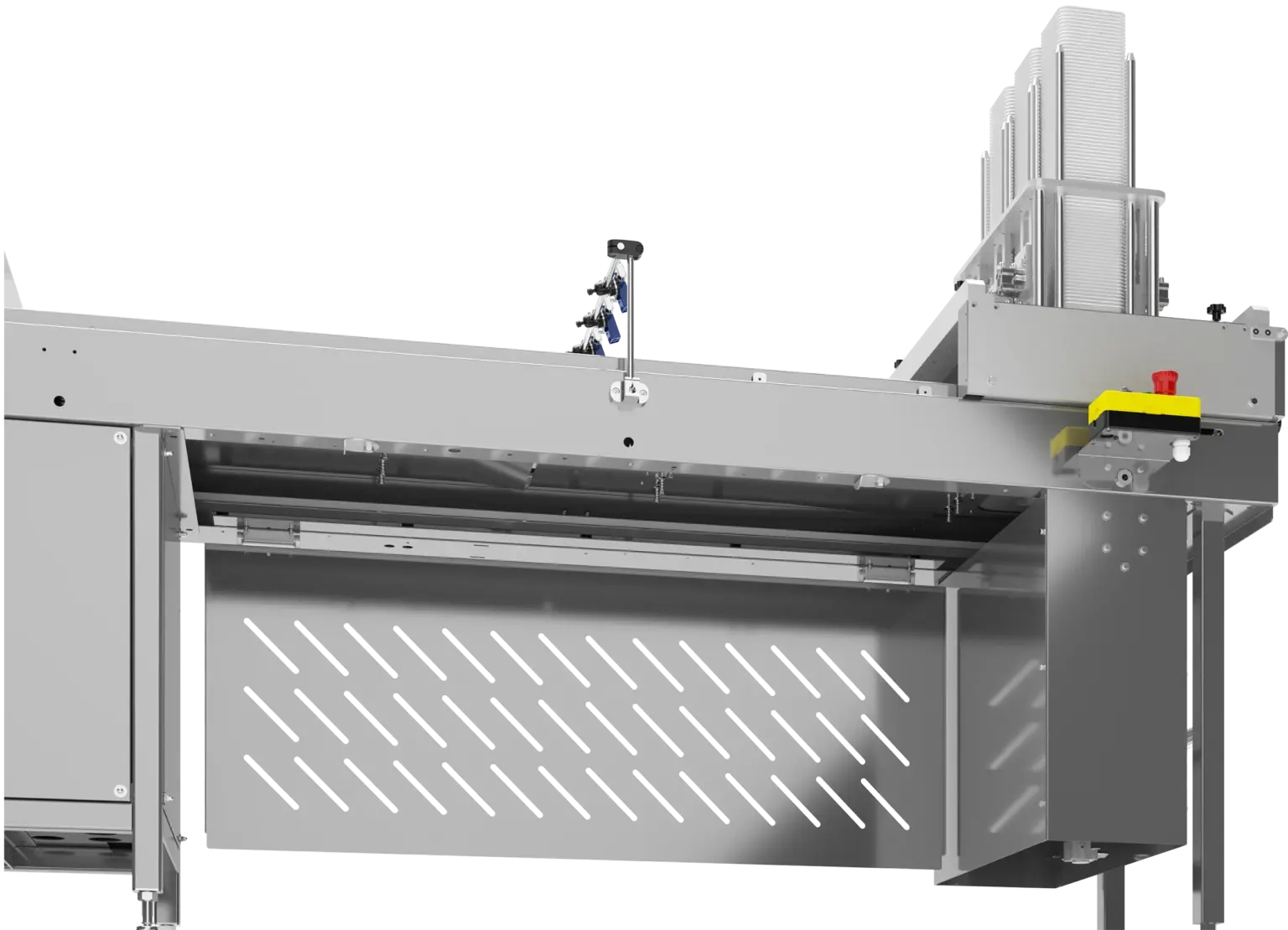

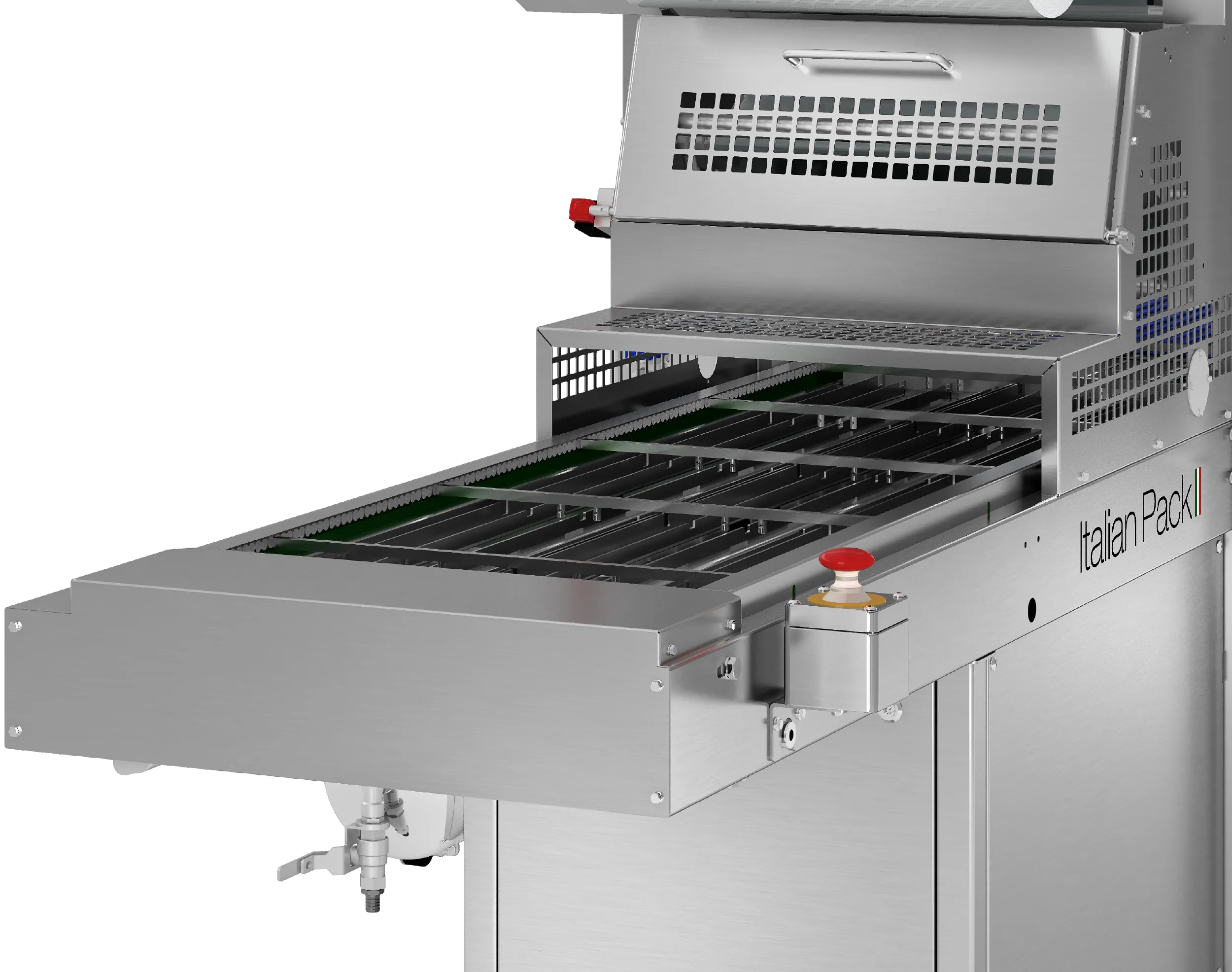

Thanks to the specially designed Trays Holder

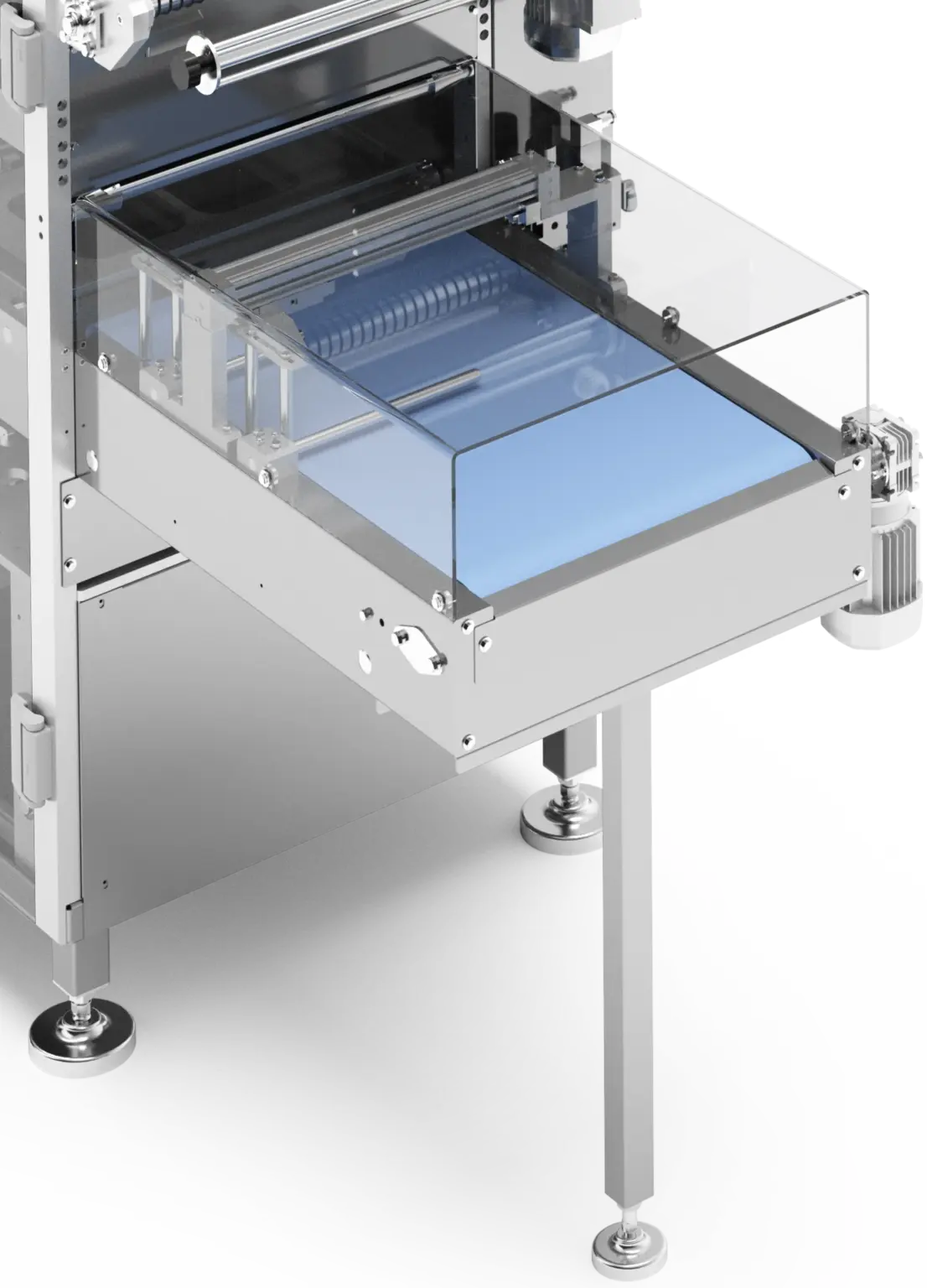

Easy Cleaning

Easy opening without tools for a daily cleaning

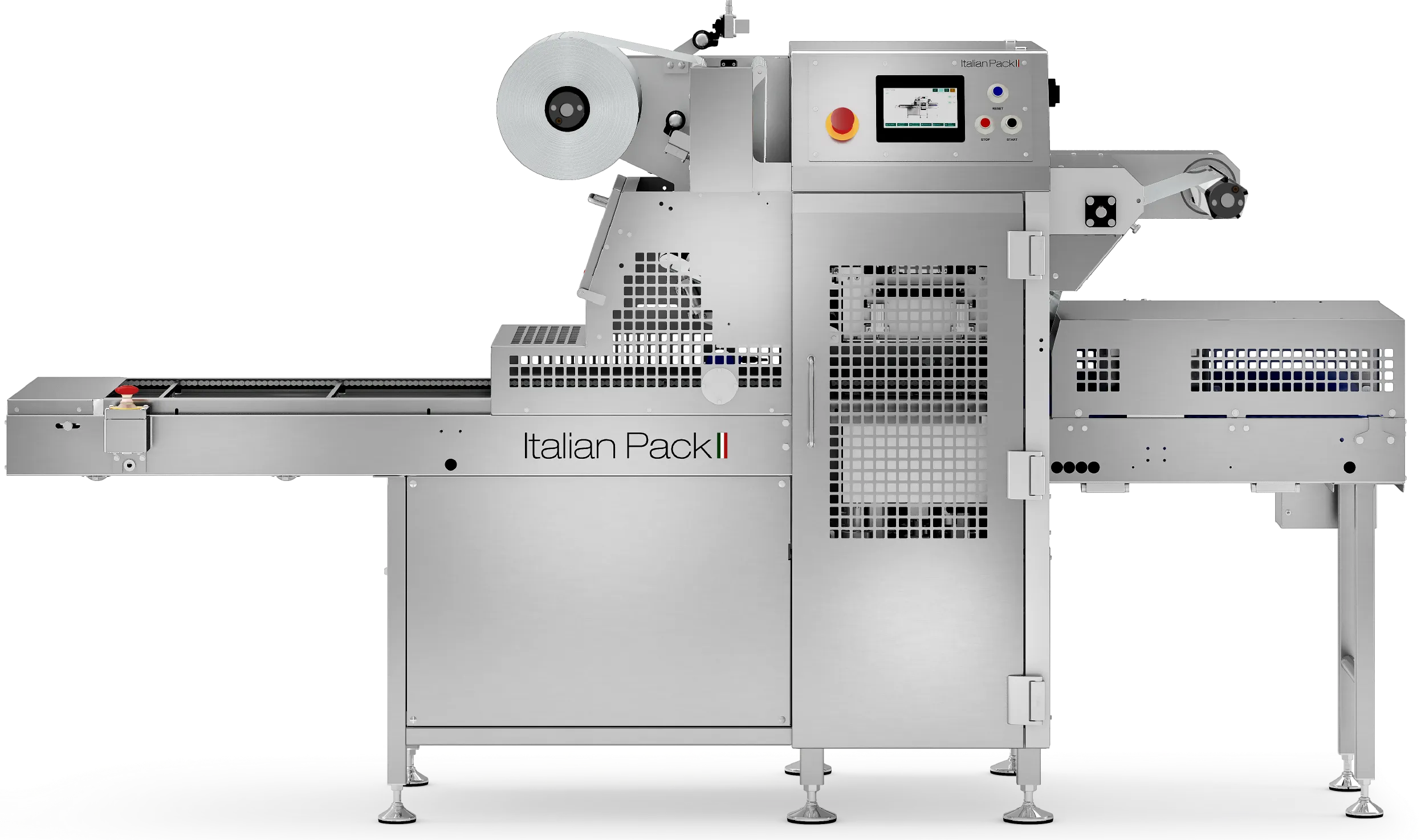

Electric Box

Electrical panel IP66 and IK10 certified AISI 304 stainless steel, wire welded frame, numbered cables, easily accessible for optimized ease of cleaning. Hinged stainless steel panel for easy opening.

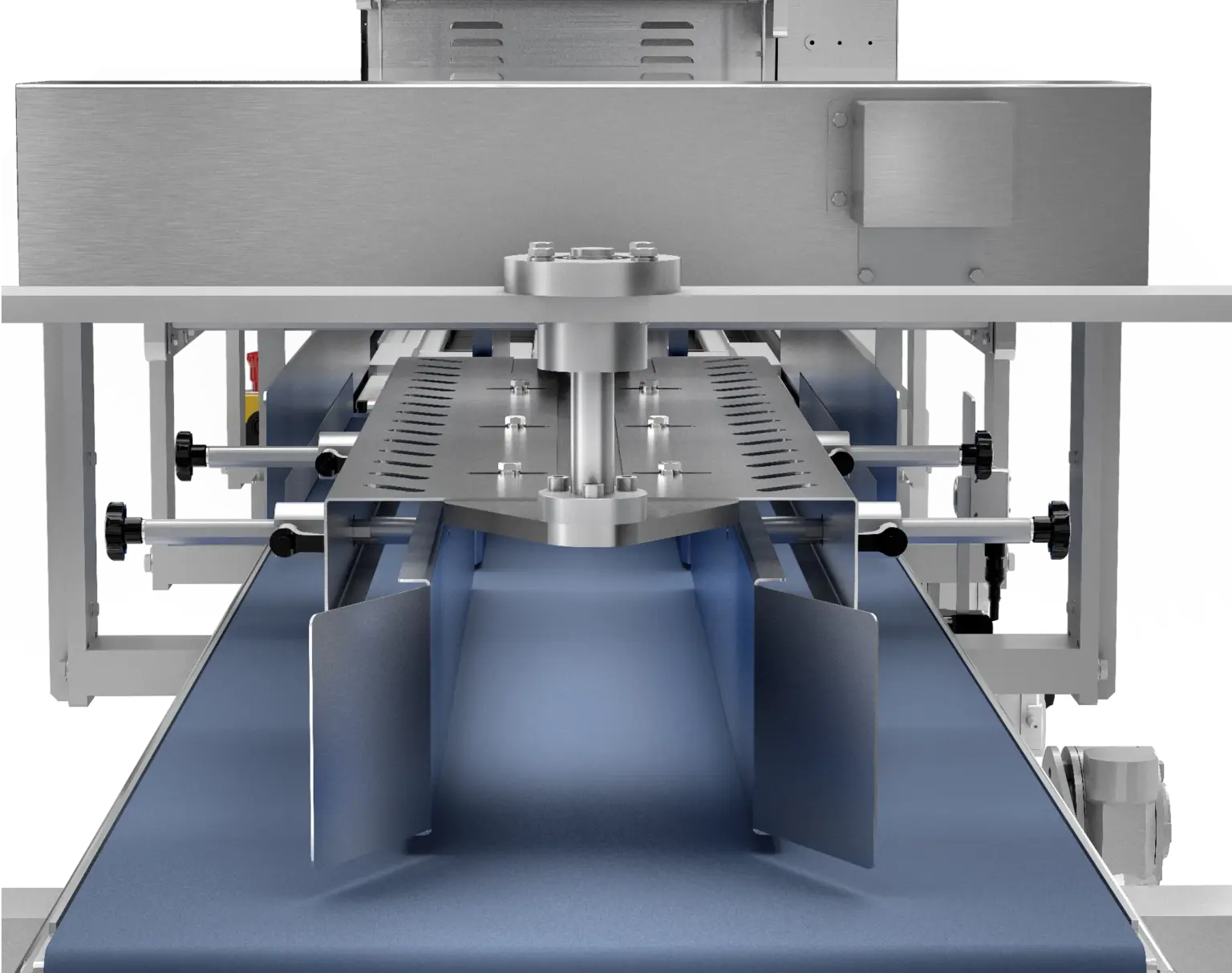

Easy access

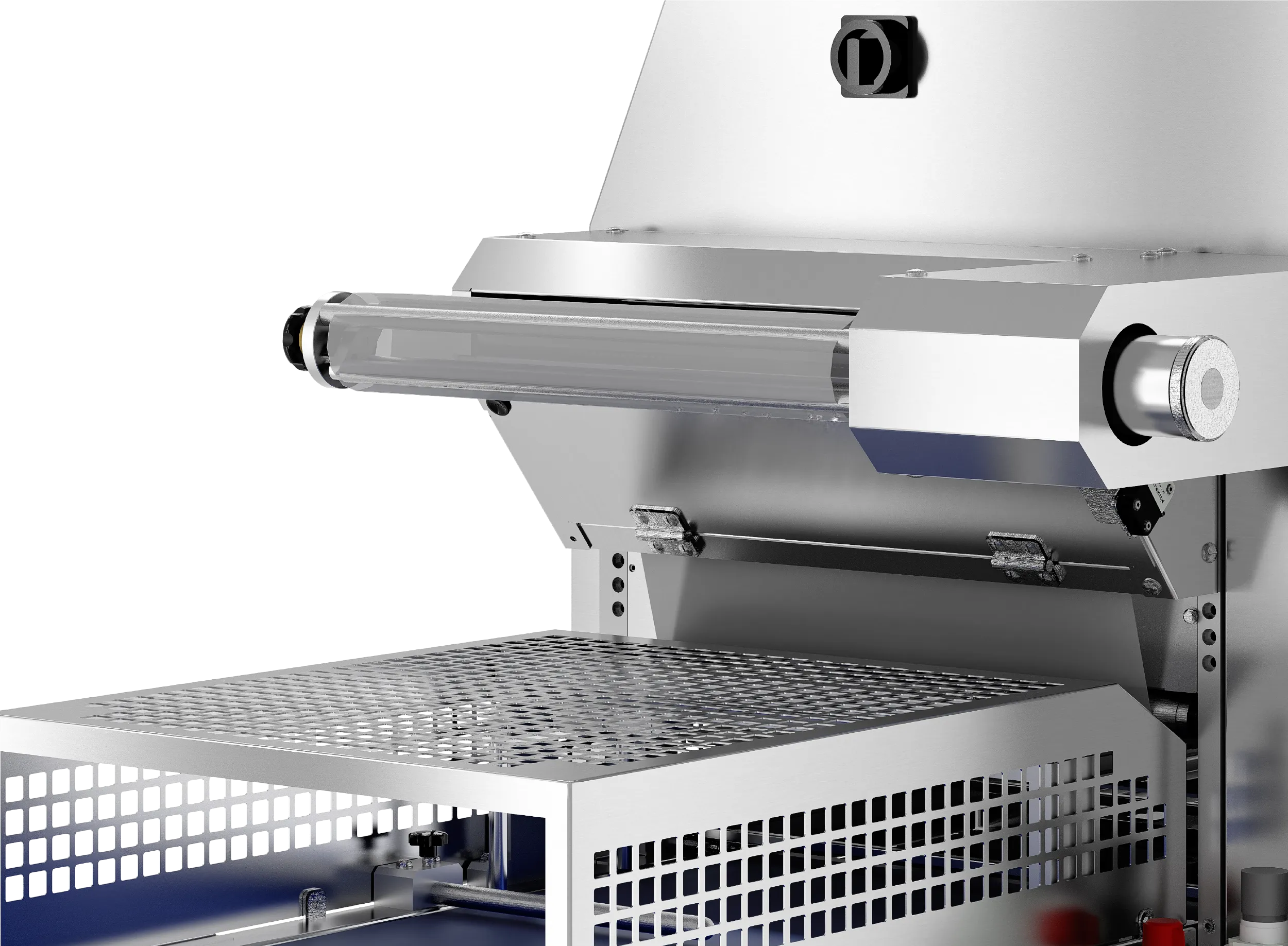

Sealing, vacuum units and electronic instantly accessible via front panel for quick and easy maintenance and cleaning operations.

Fast changing tool

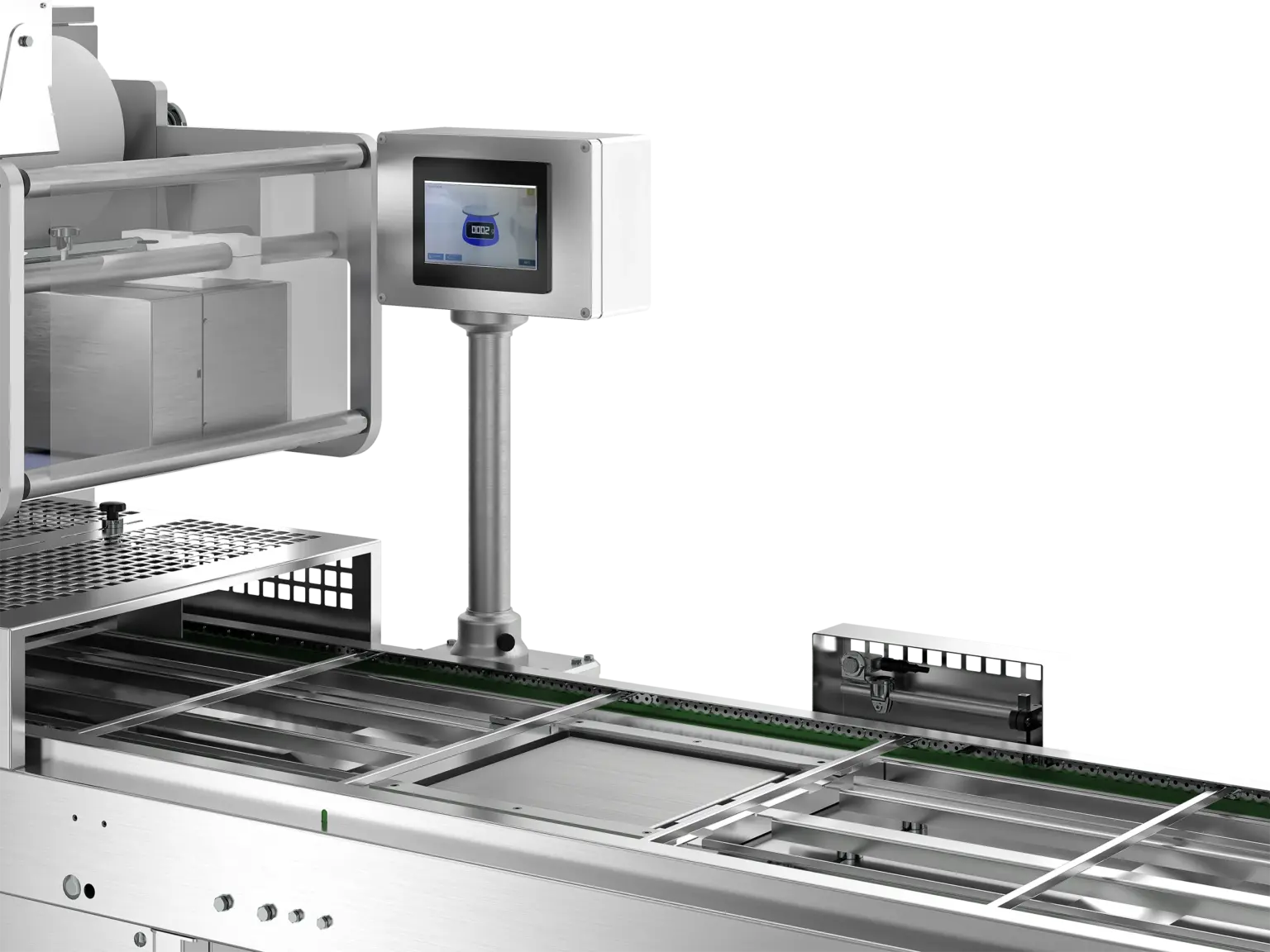

PLC Touch Screen Control Panel

7.2” PLC Touch screen, 65,000 display colors, USB port/Ethernet, 99 packaging programs, language selection, integrated temperature control, menu-driven M.A.P. parameters, skin tray and gradual vacuum.

Optional Gas Buffer Tank

Stainless steel gas buffer tank with pressure regulator.

Pre Heating

Aluminium plate with Teflon coating.

Inox push-button

Trays aligner

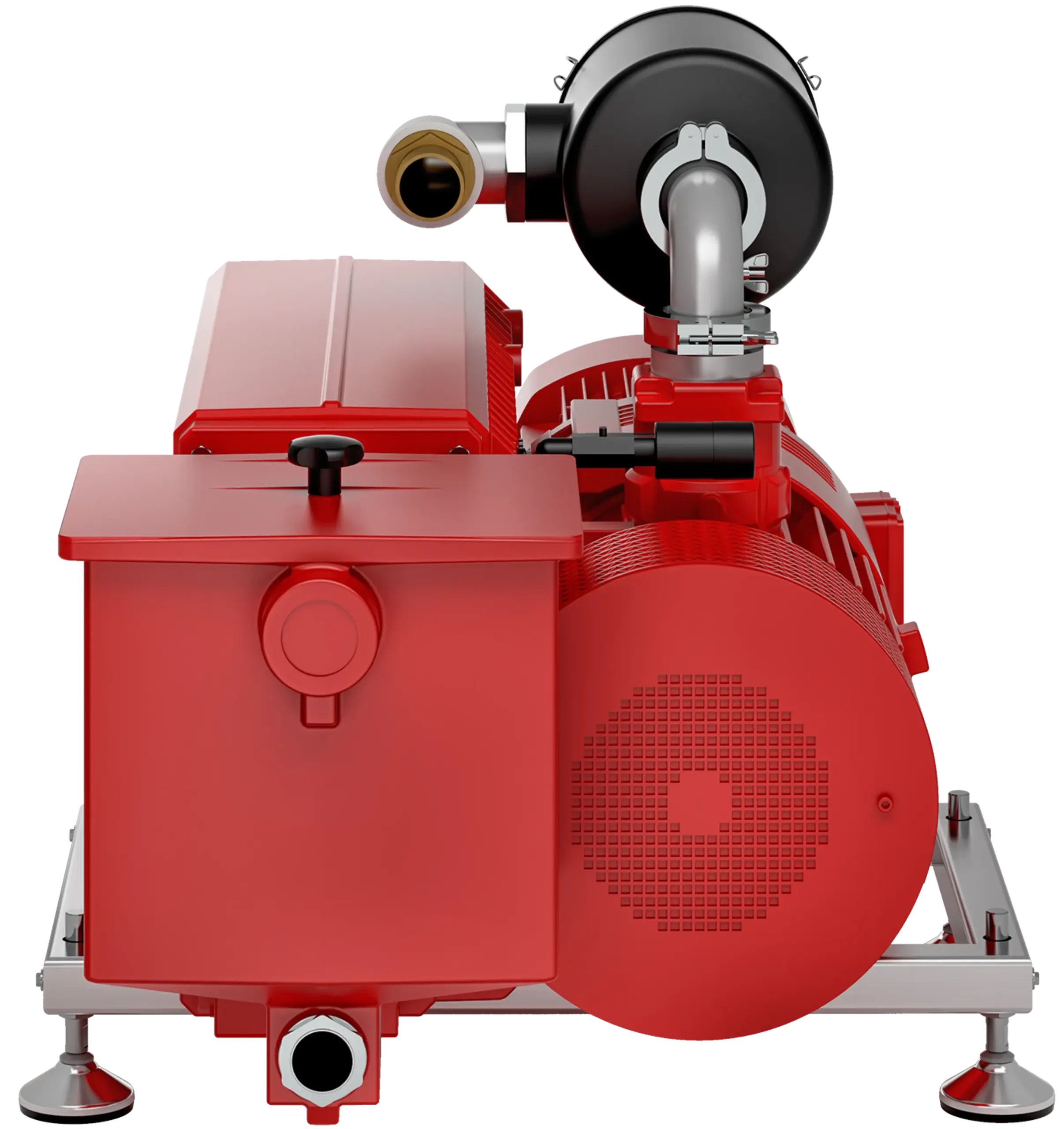

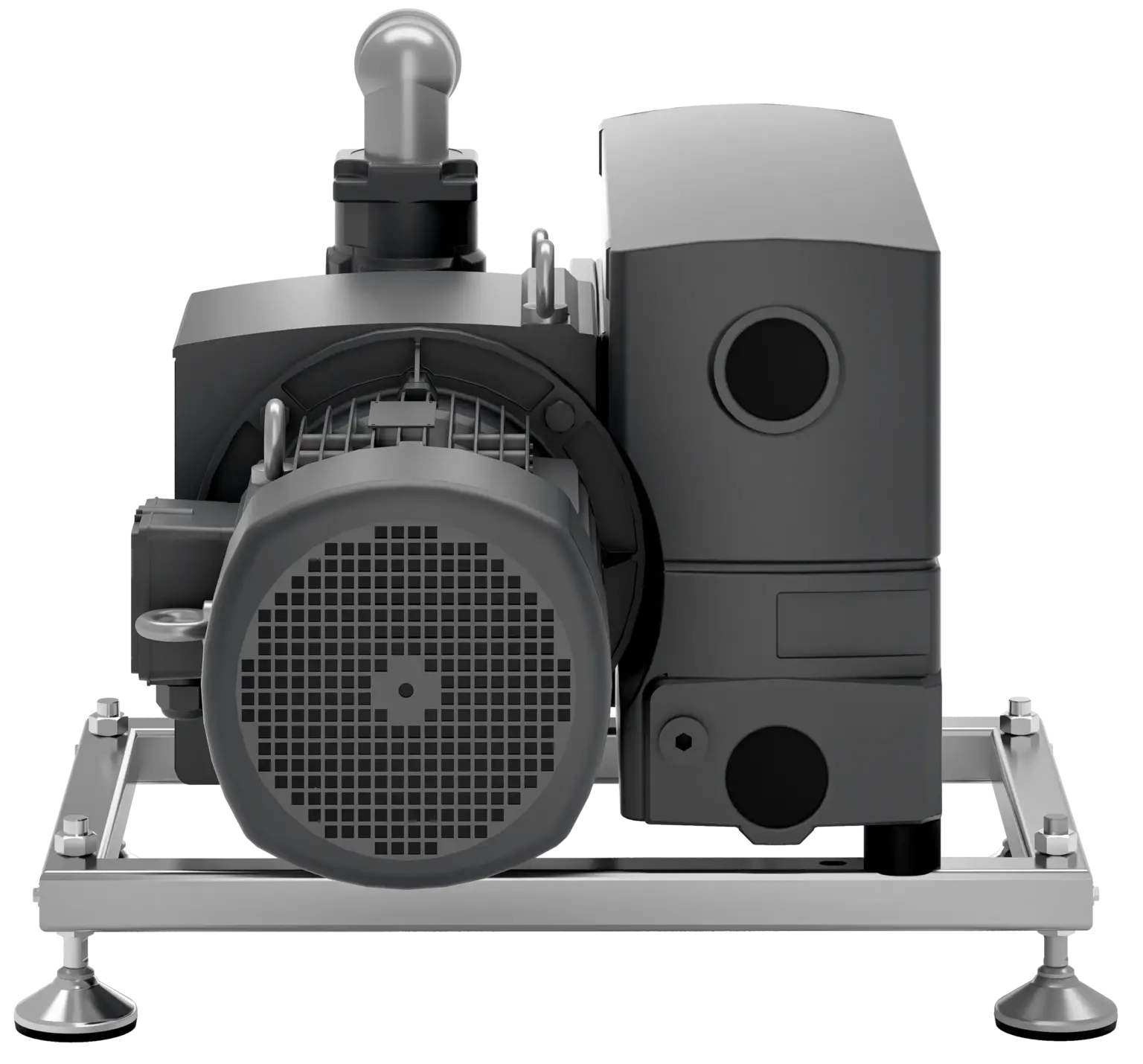

300m3/h Oxygen pump

300m3/h pump

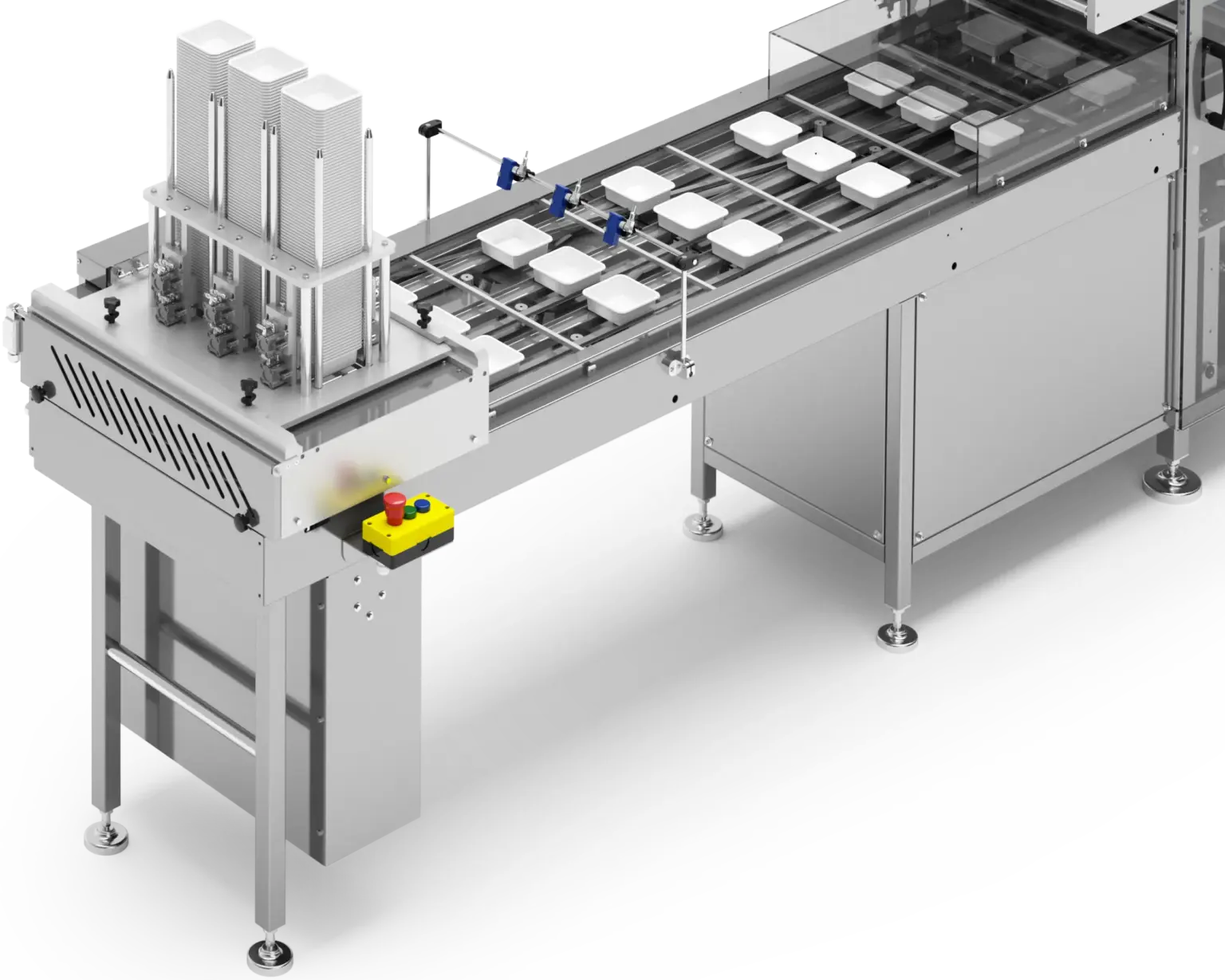

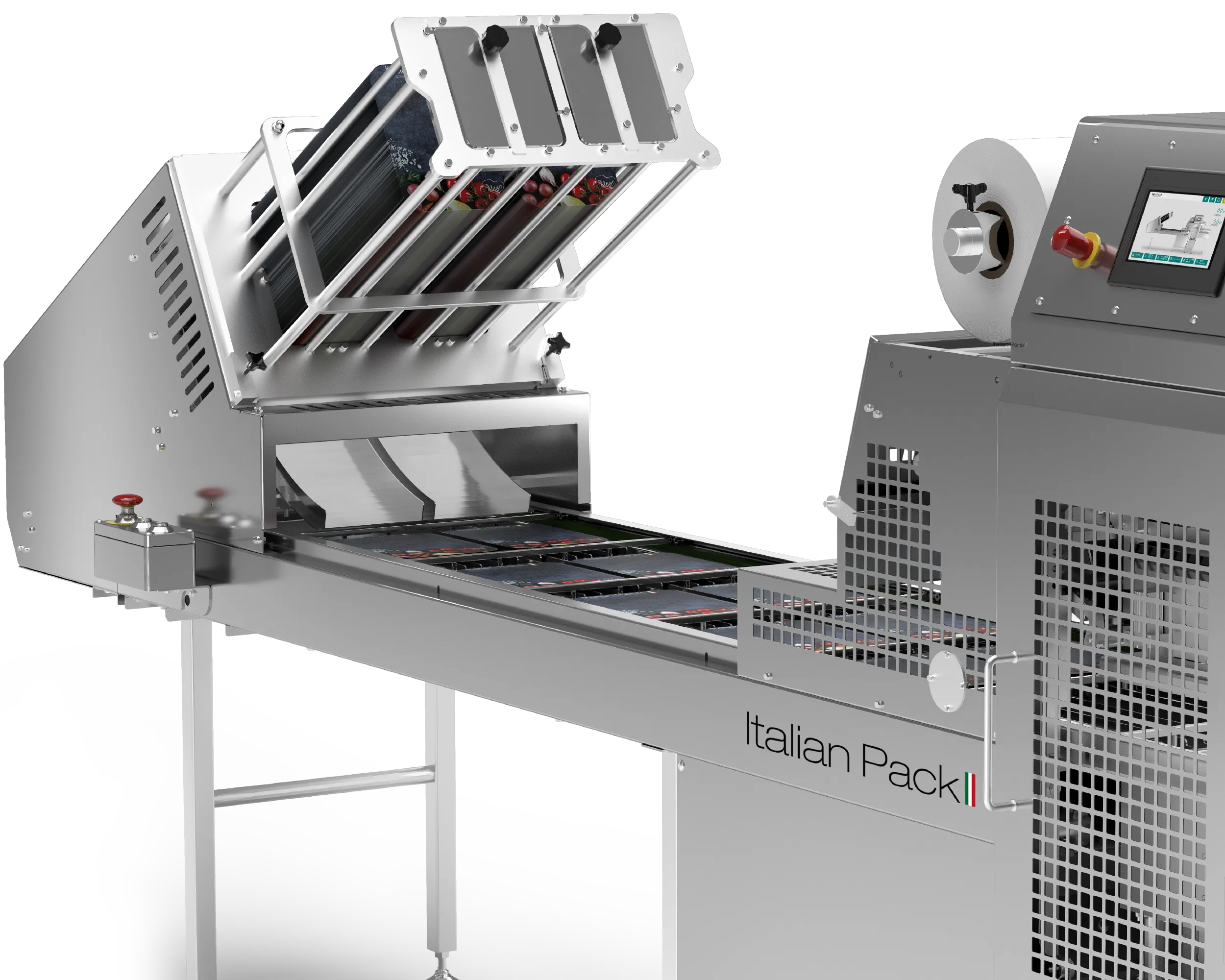

Denester

Tray denester with up to 4 lines. Quick format change available.

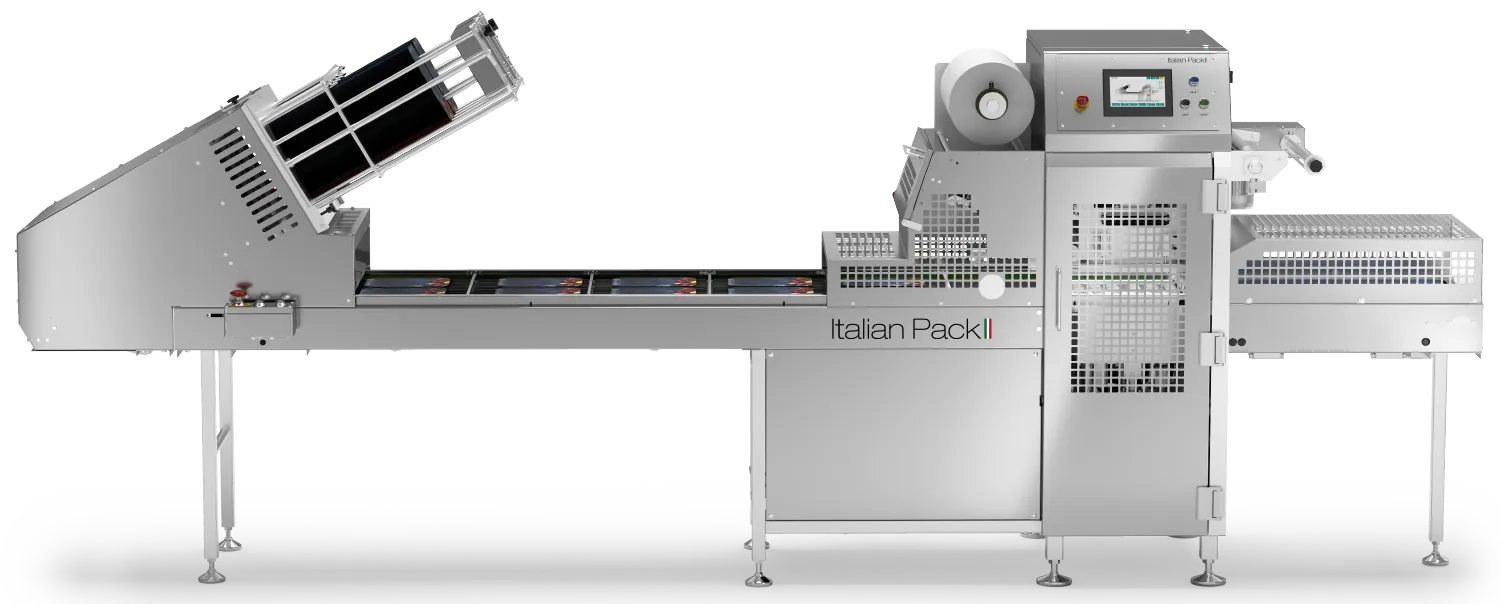

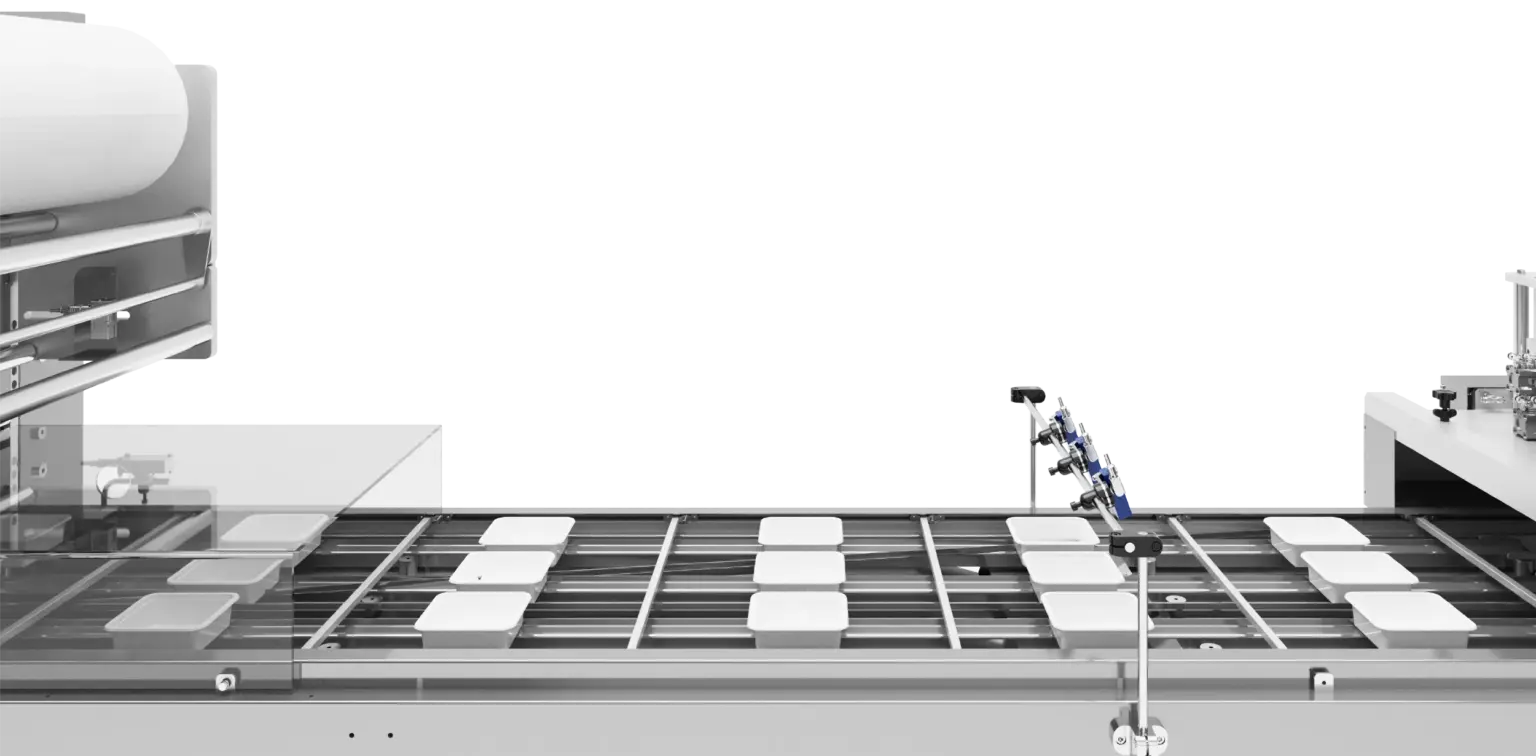

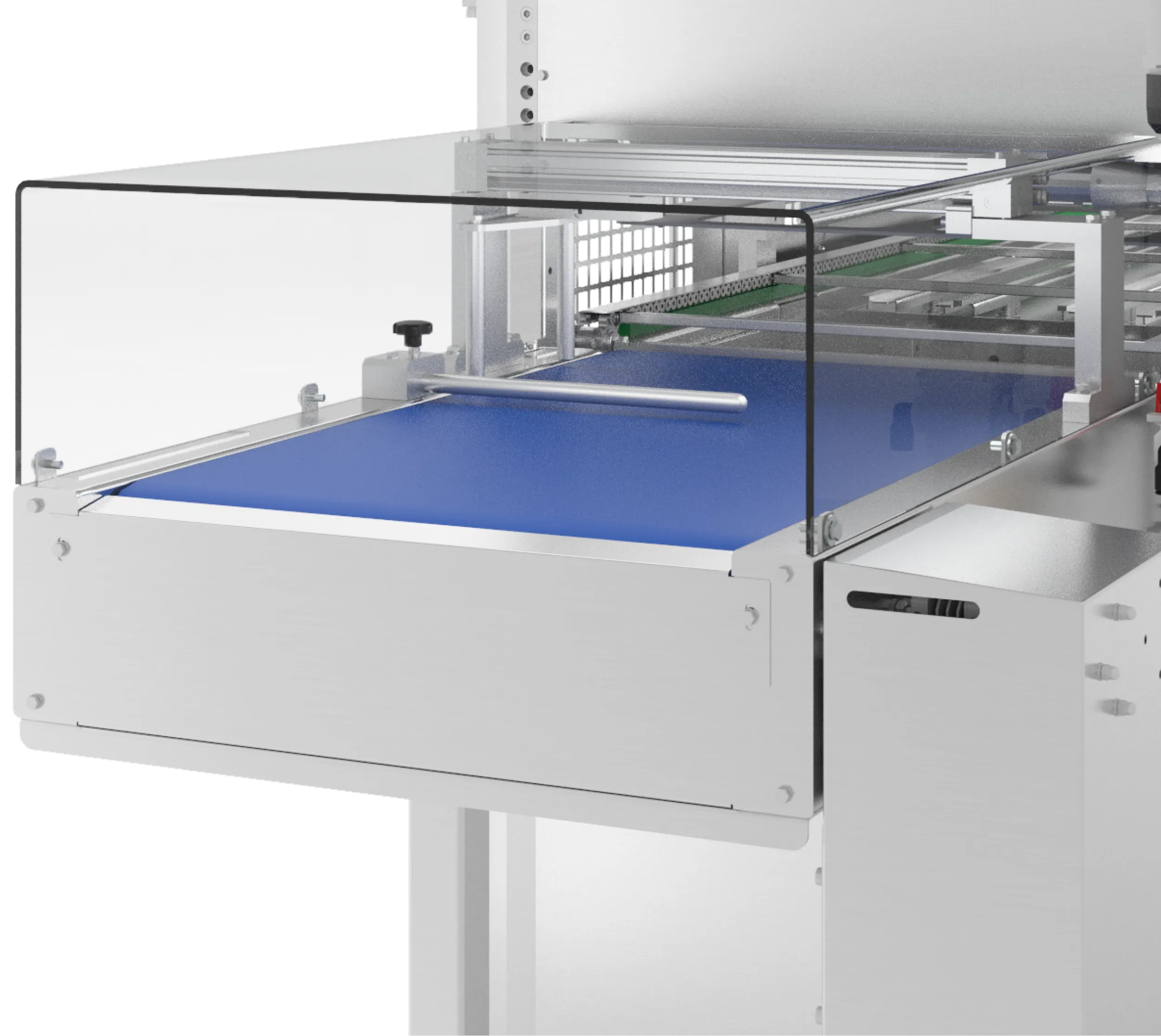

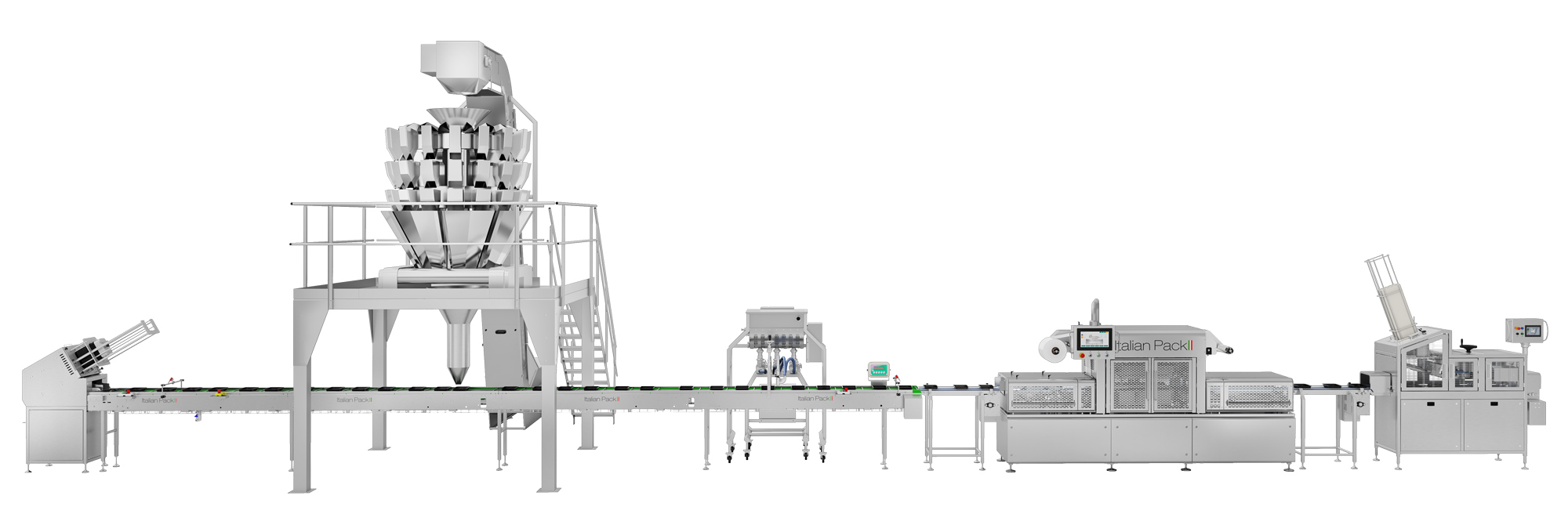

Modular Infeed Area

Infeed conveyors available in different sizes, all suitable for any custom-designed system and for integration with tray denesters, dosing machines and loading positions, also specials with food vibrators and weighers.

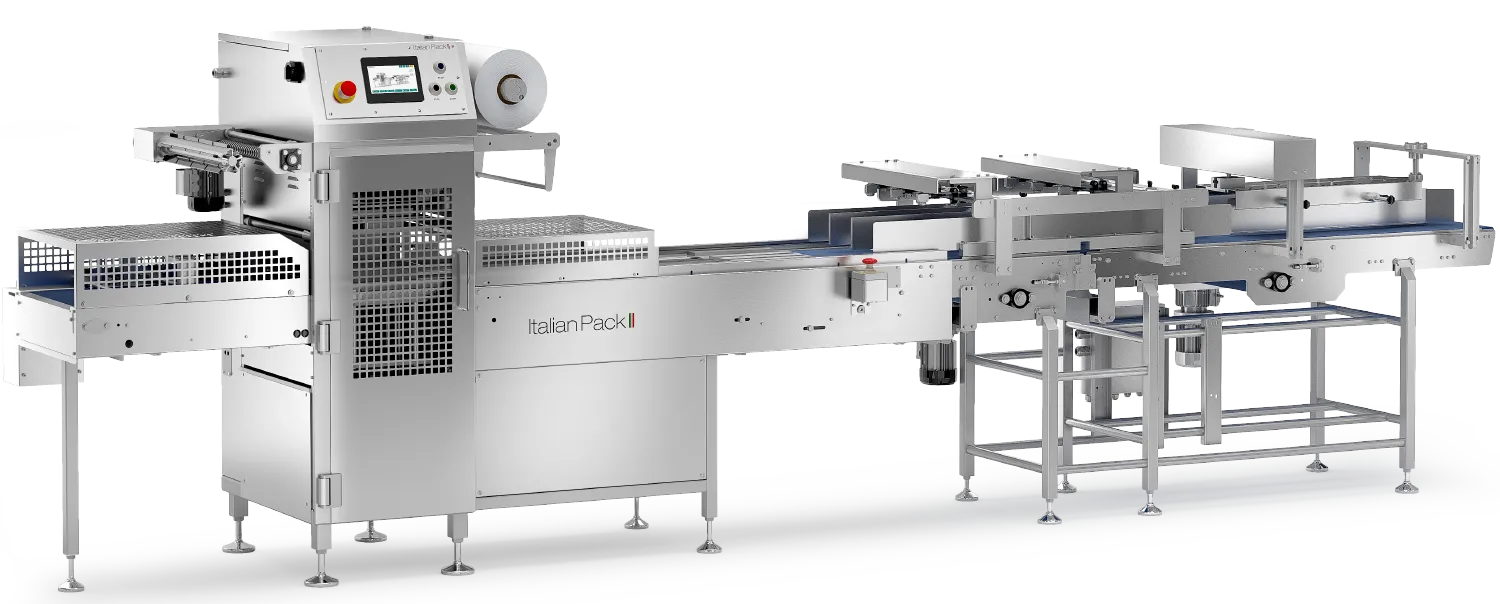

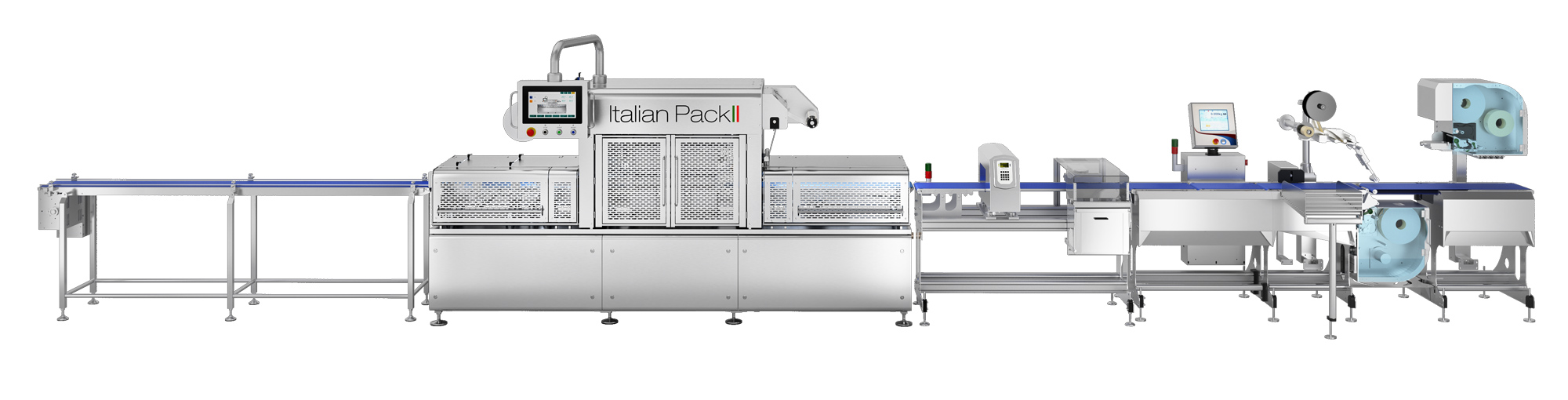

Motor-Driven Outfeed Conveyor Line

Motorized outfeed conveyor allows for the channeling of multiple tray lines into a single tray line for weighing, labelling and metal detection.

Teleservice

Remote teleservice by modem

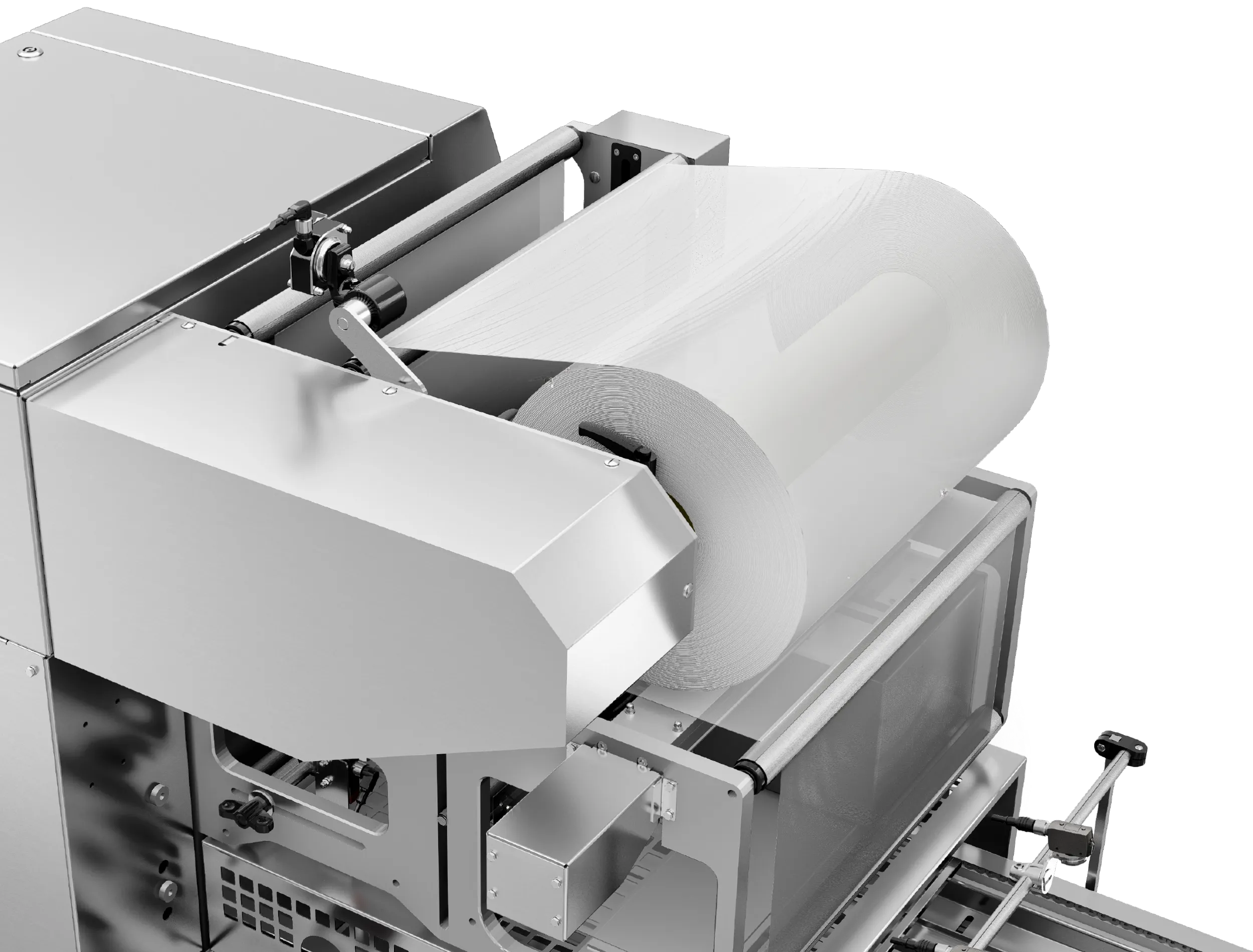

Film waste rewinding driven by brushless motor.

Film Coil Shaft Driven by Brushless Motor

Denester

Denester for Flat paper board and trays.

Expanding shafts

Film printer

Weighing scale

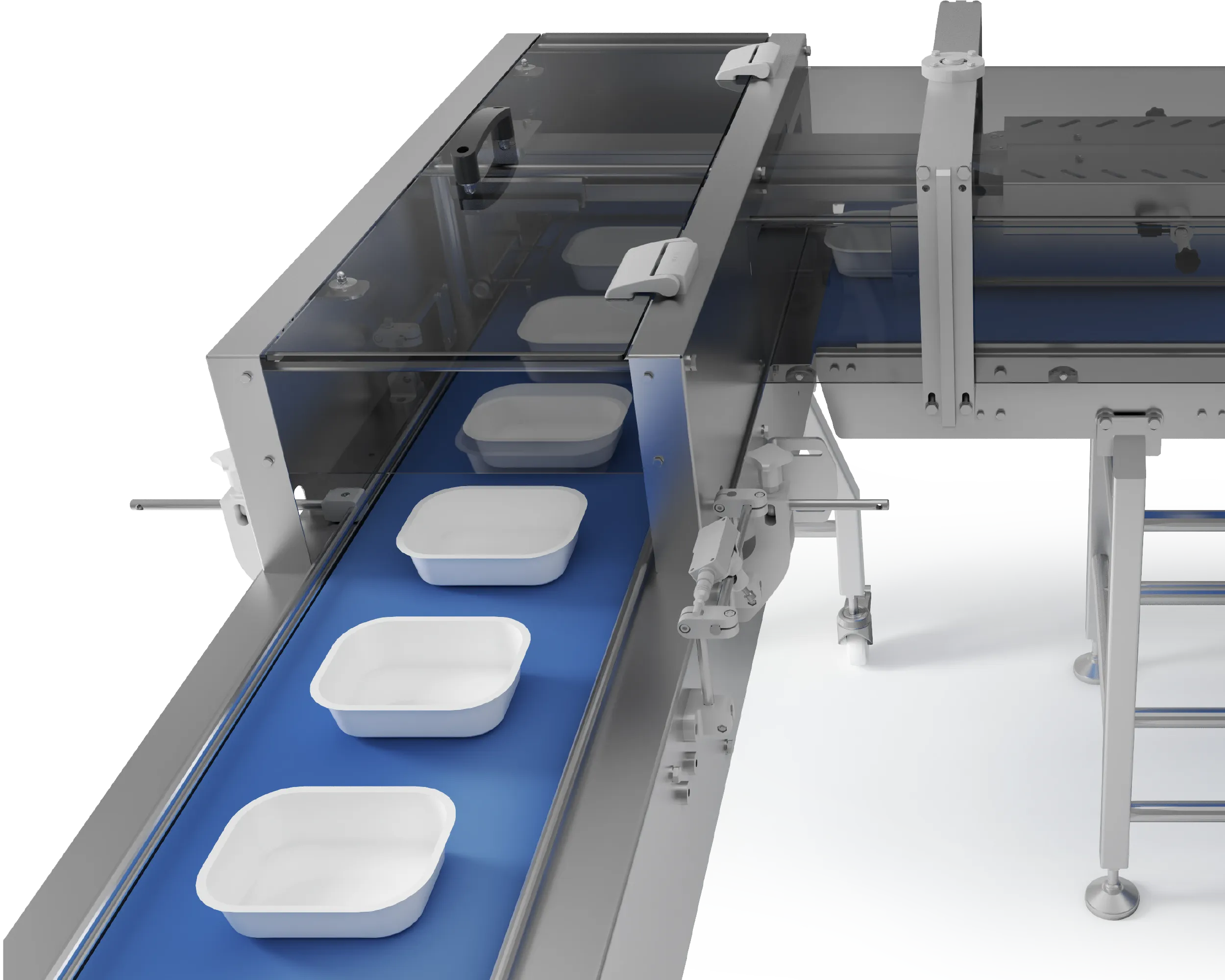

Optional 90° Infeed Conveyor

Automatic tray infeed system with a 90 degree conveyor from 1 to several tray lines

Optional Automatic Infeed Conveyor

Automatic tray in-line conveyor from 1 to several tray lines.

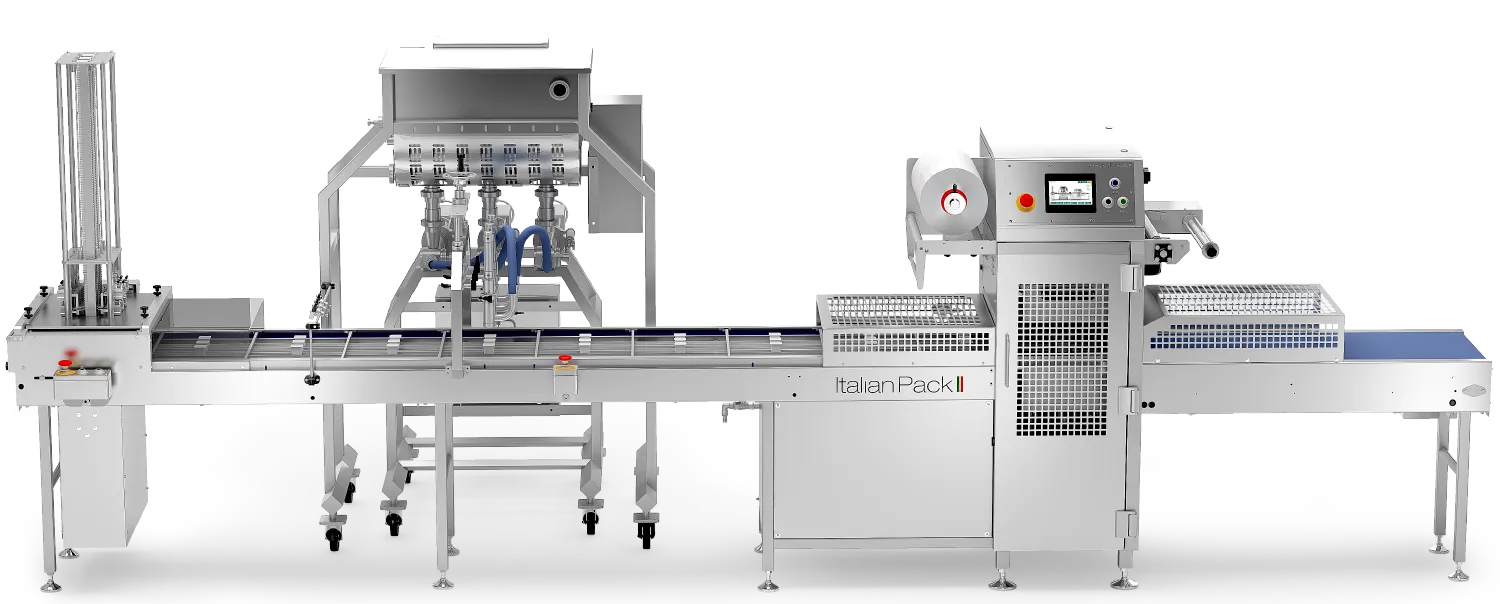

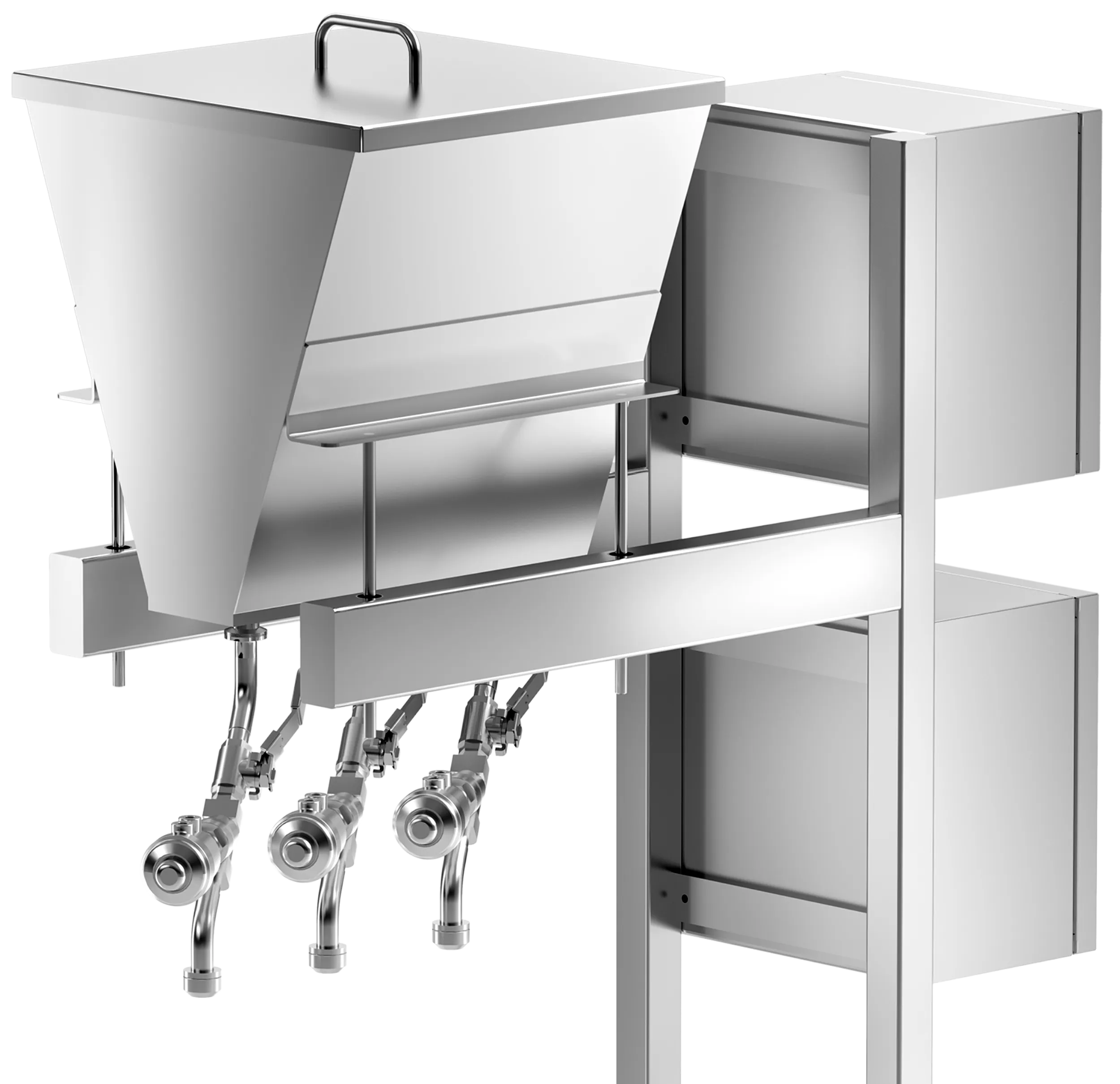

Filling unit

Complete unit for product dosage

Perseus Stretch

Perseus Stretch Features

Film waste rewinding by brushless motor

Film waste expanding shaft

Motorized Outfeed Conveyor

Film coil shaft driven by brushles motor

Film coil shaft driven by brushless motor

Film waste rewinding by brushless motor

/// Special lines ///

-

DEN35

Denester

- Conveyor

- Automatic filling units

- Argo 720

-

LID30

Automatic lid applier

- Conveyor

- Metal detector

- Electronical weigher

- Lower labelling machine

- Upper labelling machine

Denester

Italianpack, with its long-standing experience gained in 30 years of business, has focused on the development of an AUTOMATIC DENESTER. The main purpose of this solution is to support the trends of the sector in which it operates, aiming at increasingly complete automation of the packaging lines.

Automatic lid applier

Italianpack, a leading company in the production of traysealing machines, is pleased to present its new AUTOMATIC LID30 LID APPLIER.