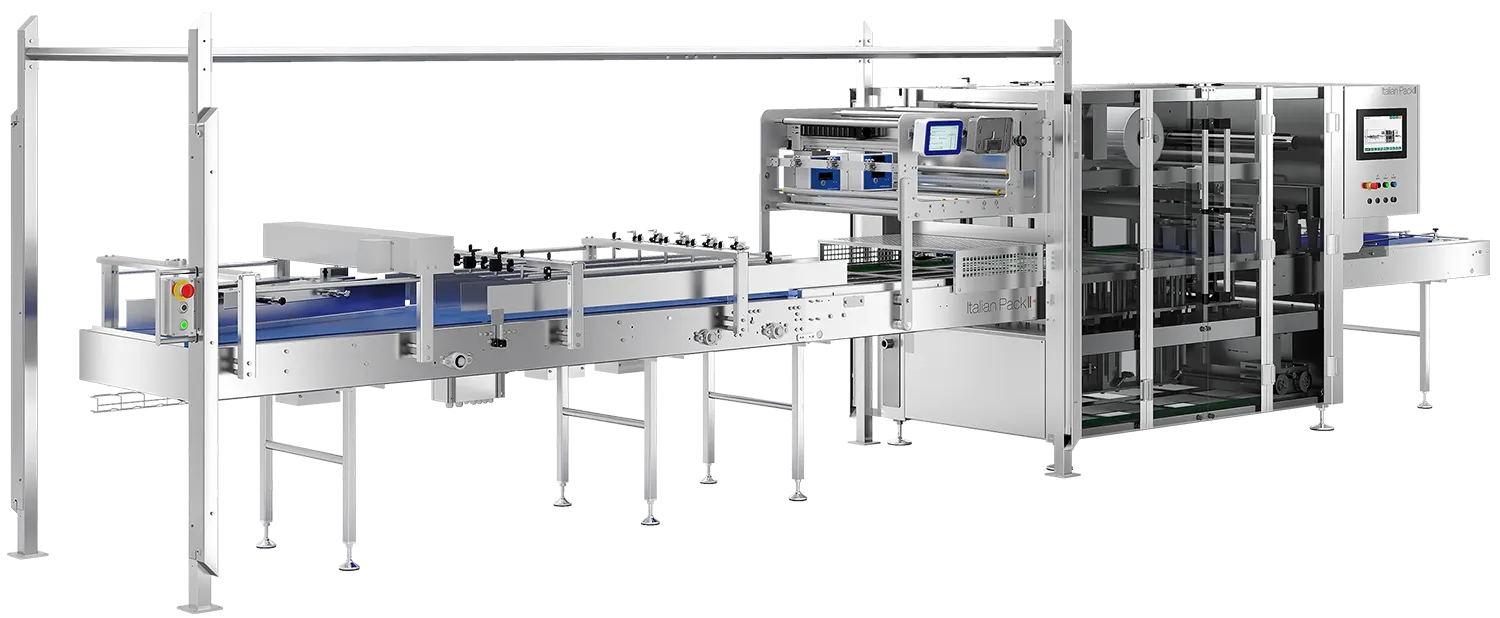

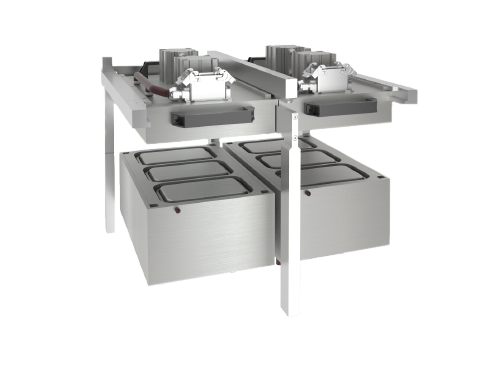

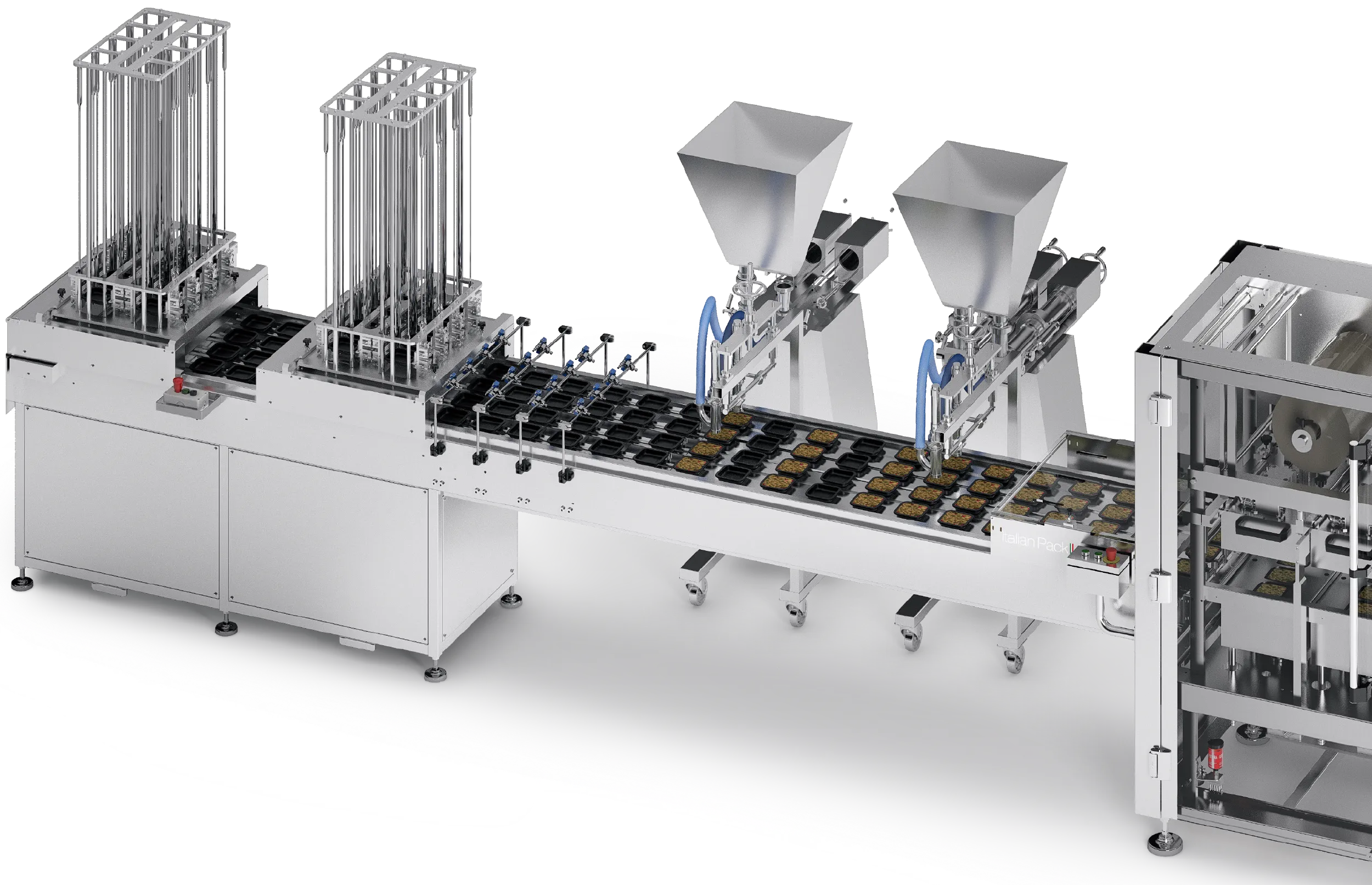

Configuration with up to three molds

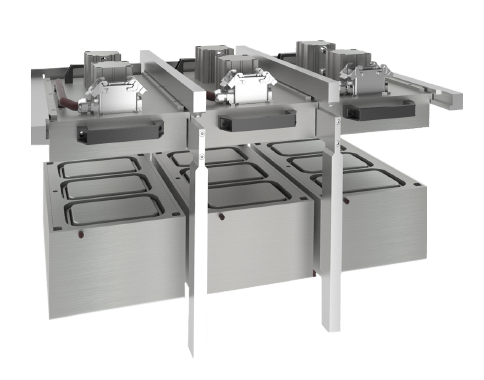

Technologies

1 Tool - 7 Technologies

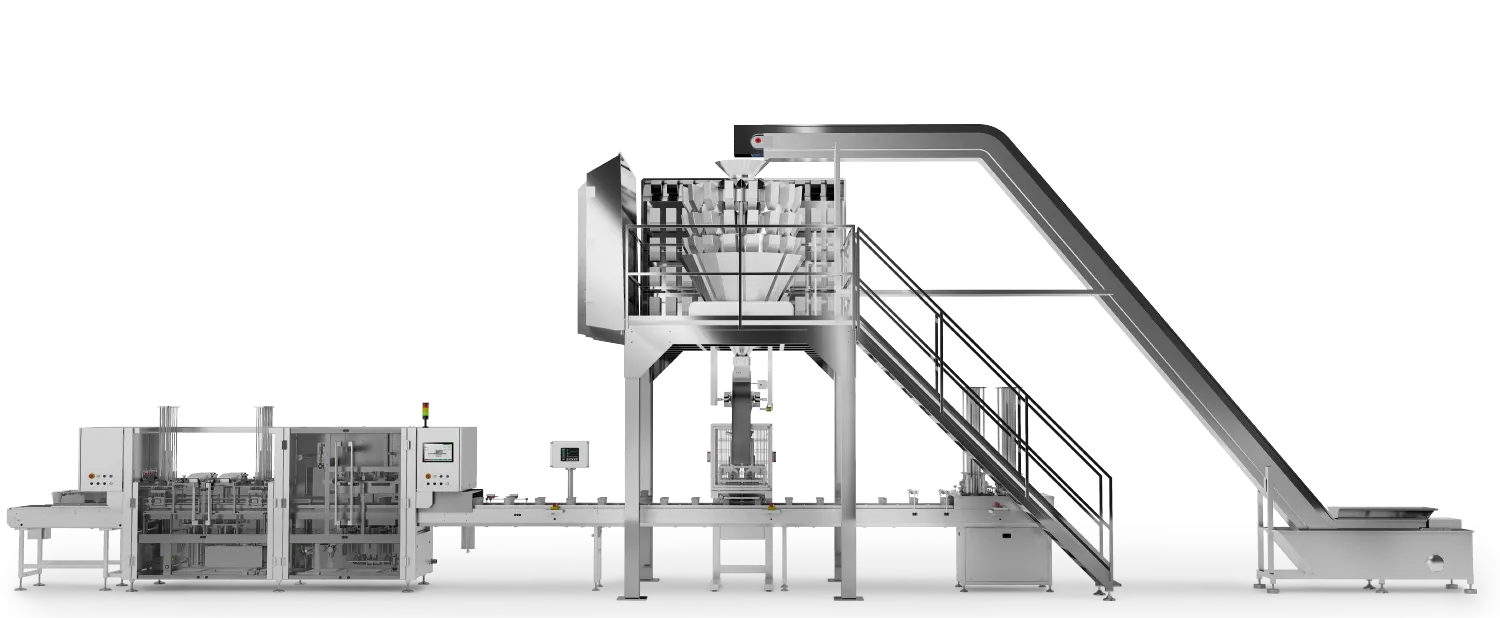

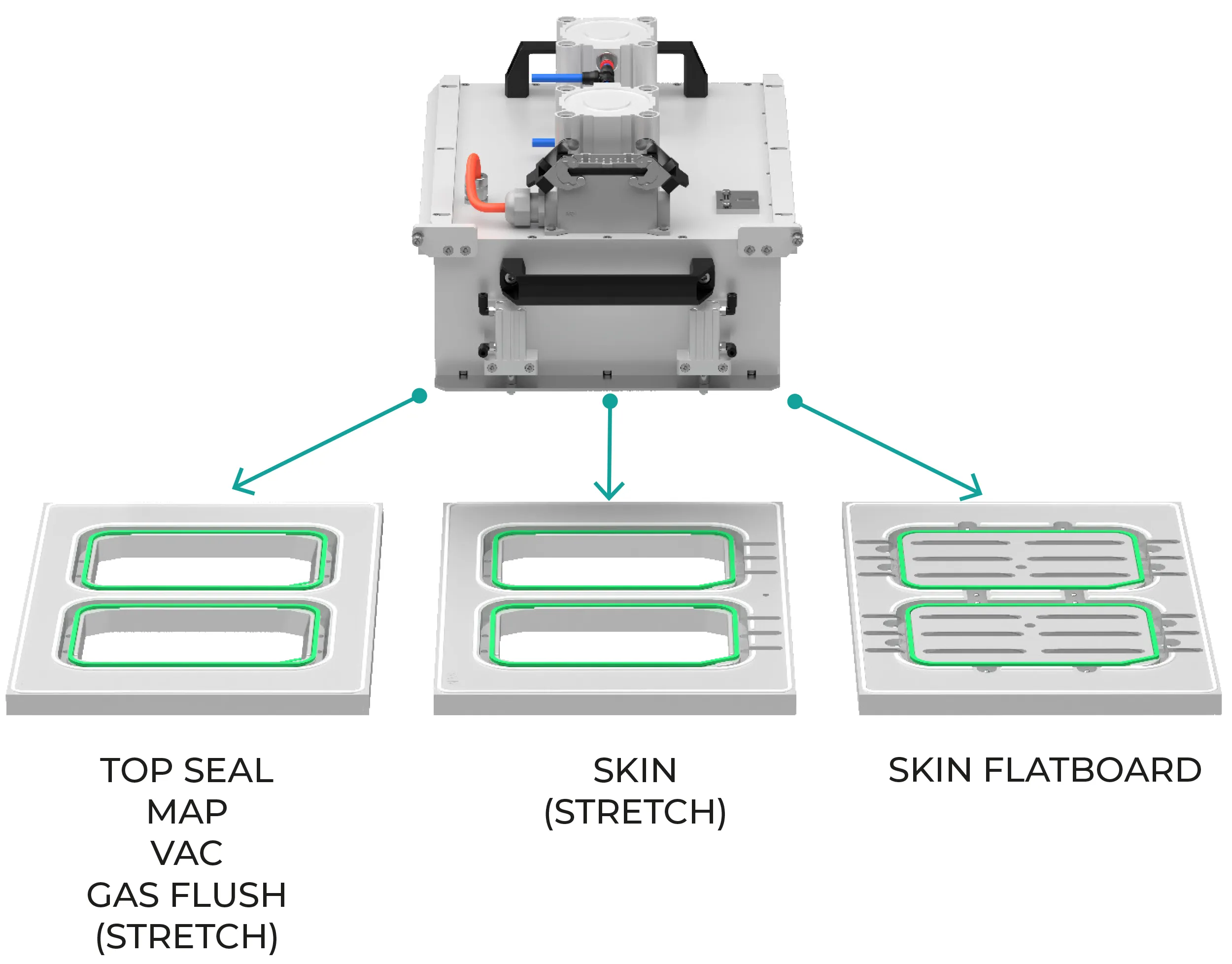

Thanks to the specially designed Trays Holder

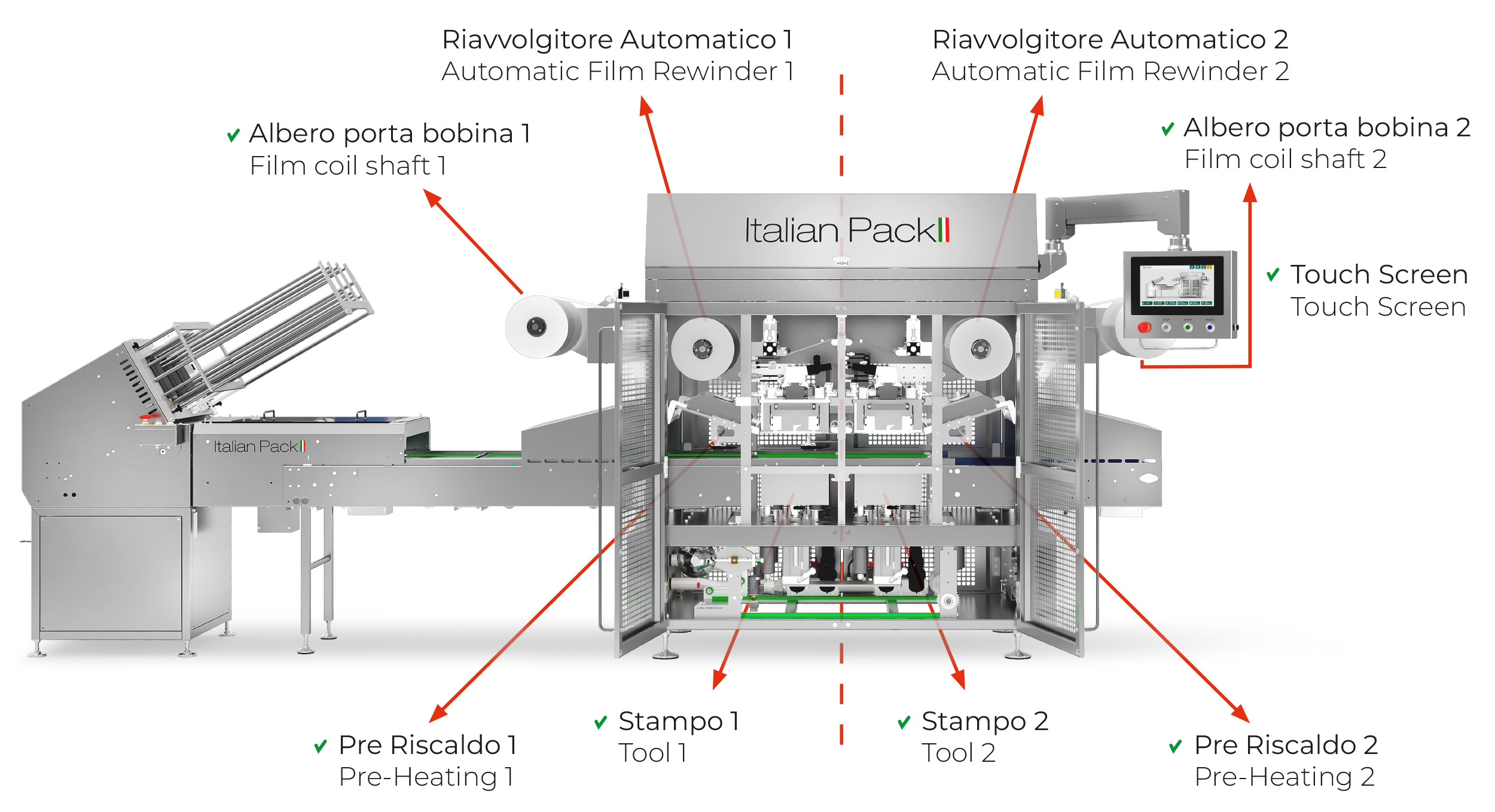

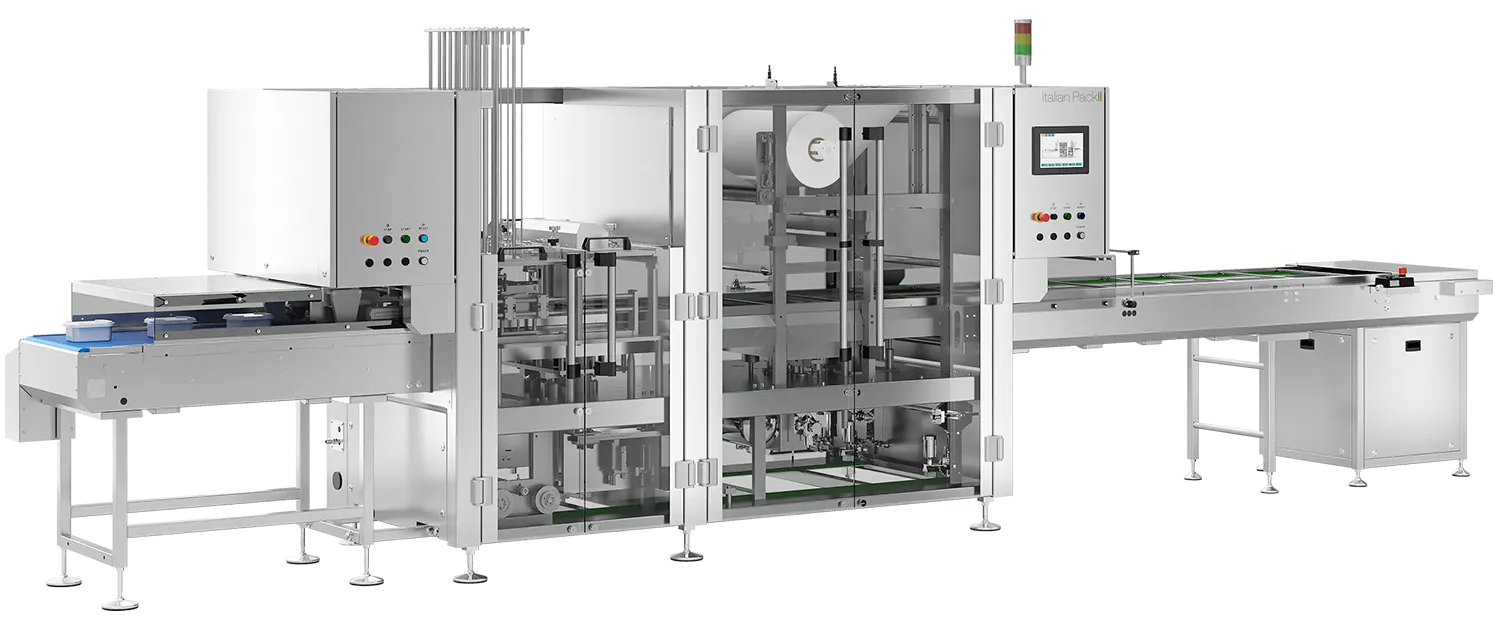

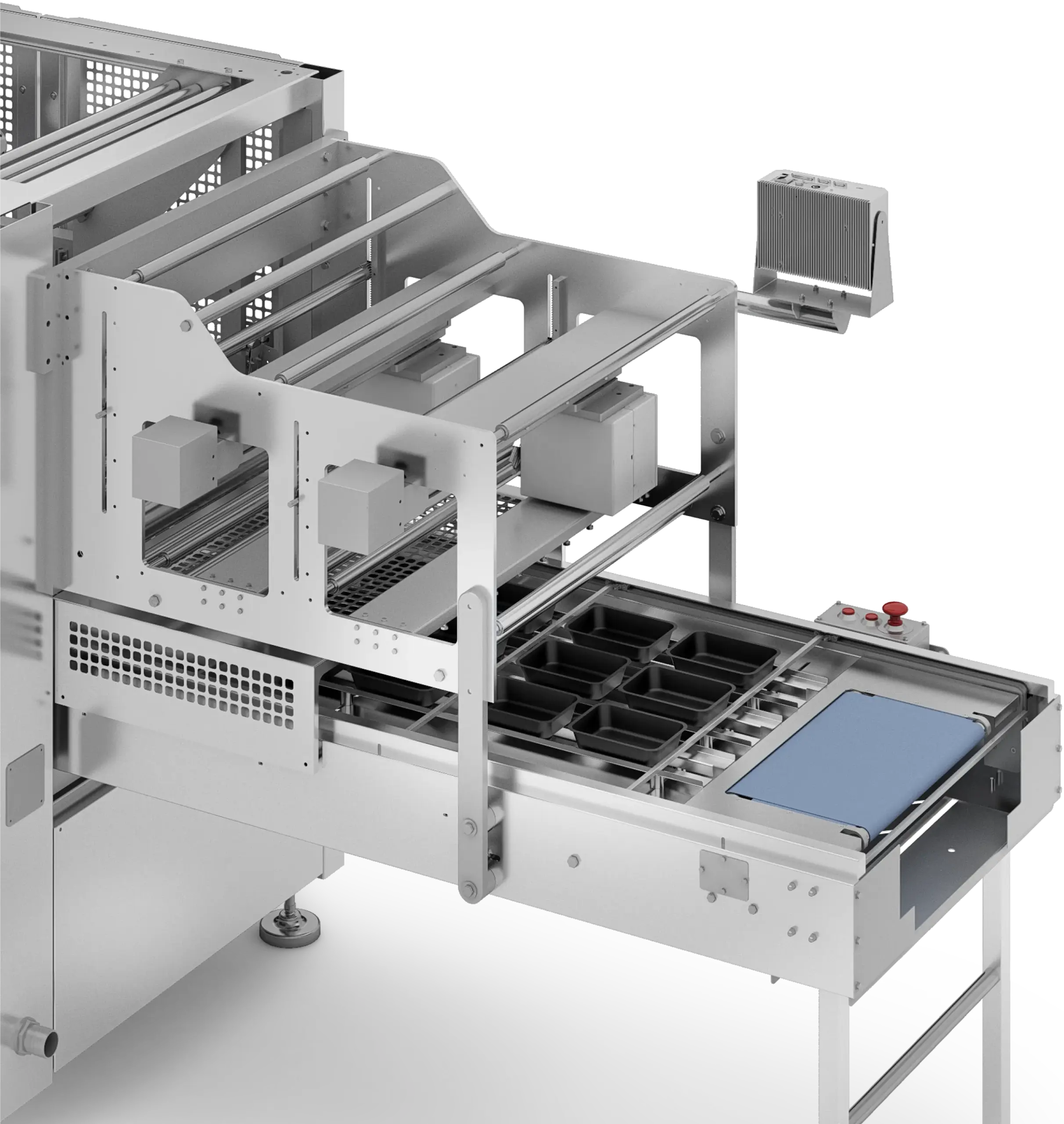

Touch screen control panel

15,6” color Touch Screen TFT JSMART 715 EXOR with quad core CPU with 16 million colors and a multitouch screen, integrated teleservice and “4.0 Industry” ready.

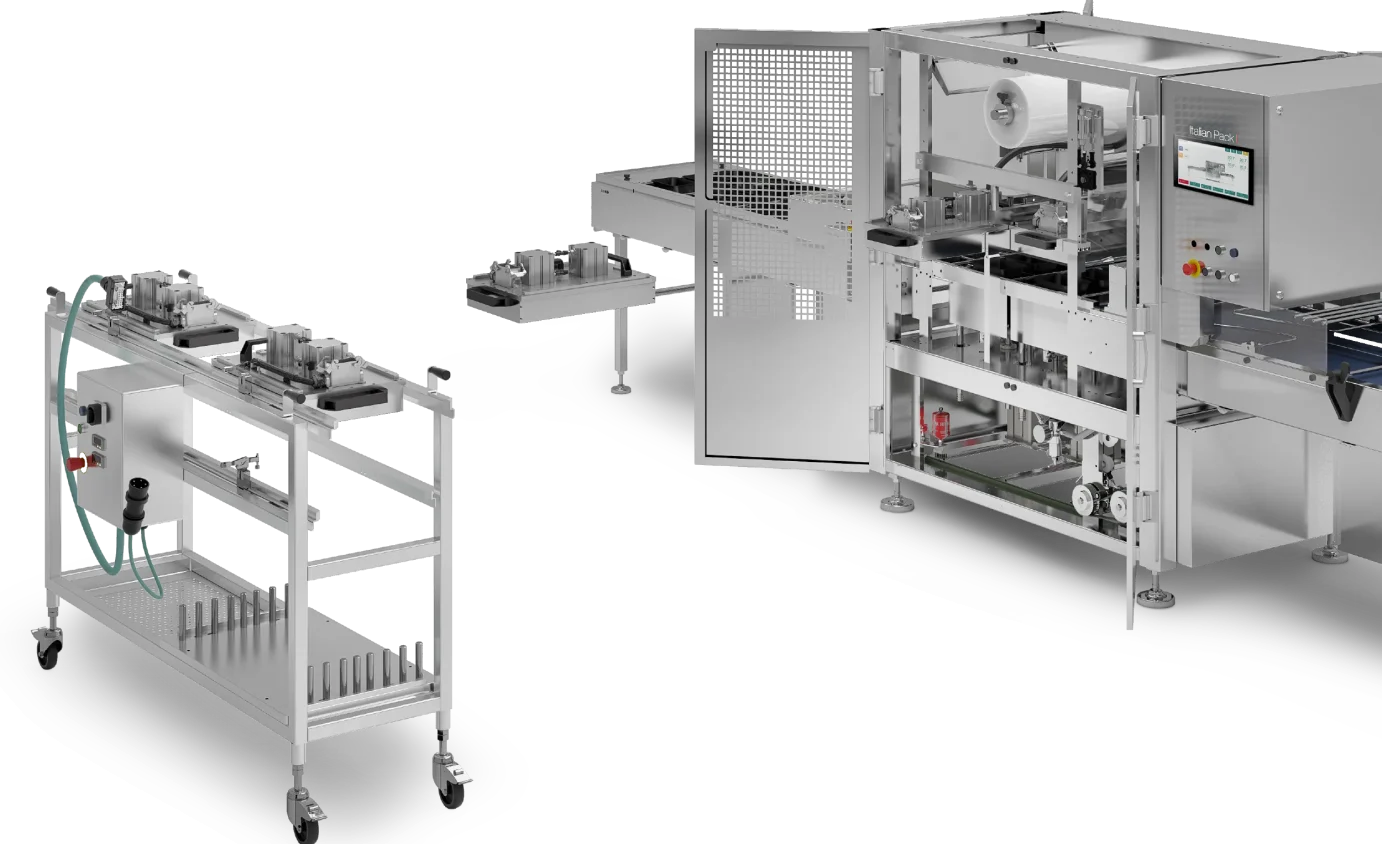

Easy Access

Complete and easy access to the sealing, vacuum and catenary groups through the front door for quick and easy maintenance and sanitation.

Busch Pump

Busch Pump

Electric Box

Electrical panel IP66 and IK10 certified AISI 304 stainless steel, wire welded frame, numbered cables, easily accessible for optimized ease of cleaning. Hinged stainless steel panel for easy opening.

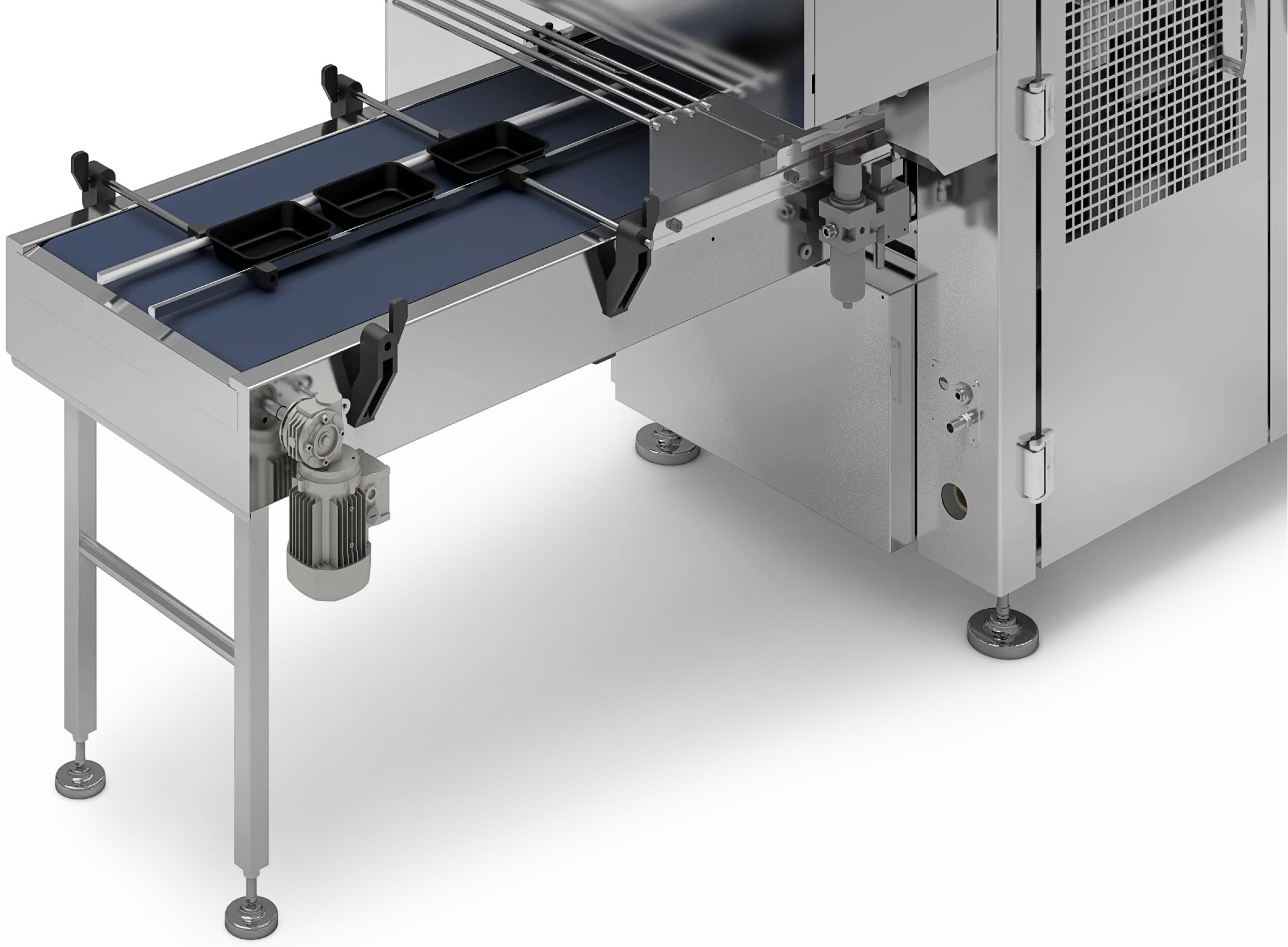

Motorized Outfeed Conveyor

Motorized outfeed conveyor allows for the channeling of multiple tray lines into a single tray line for weighing, labelling and metal detection.

Film waste rewinding by brushless motor

Electrical panel IP66 and IK10 certified AISI 304 stainless steel, wire welded frame, numbered cables, easily accessible for optimized ease of cleaning. Hinged stainless steel panel for easy opening.

Mold Change Trolley

Stainless steel trolley for easy, tool-less die-change for maximum safety

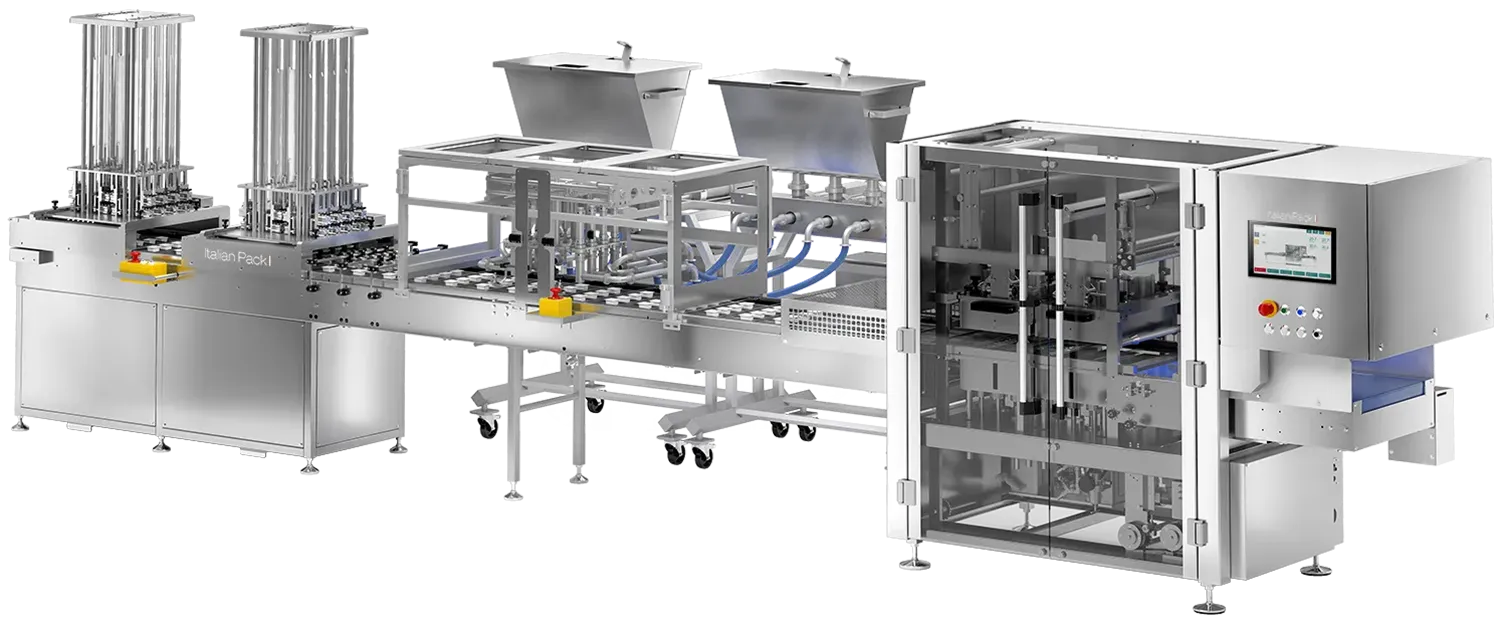

Automated Dosing Units

Automatic dosing of solids, liquids and granules.

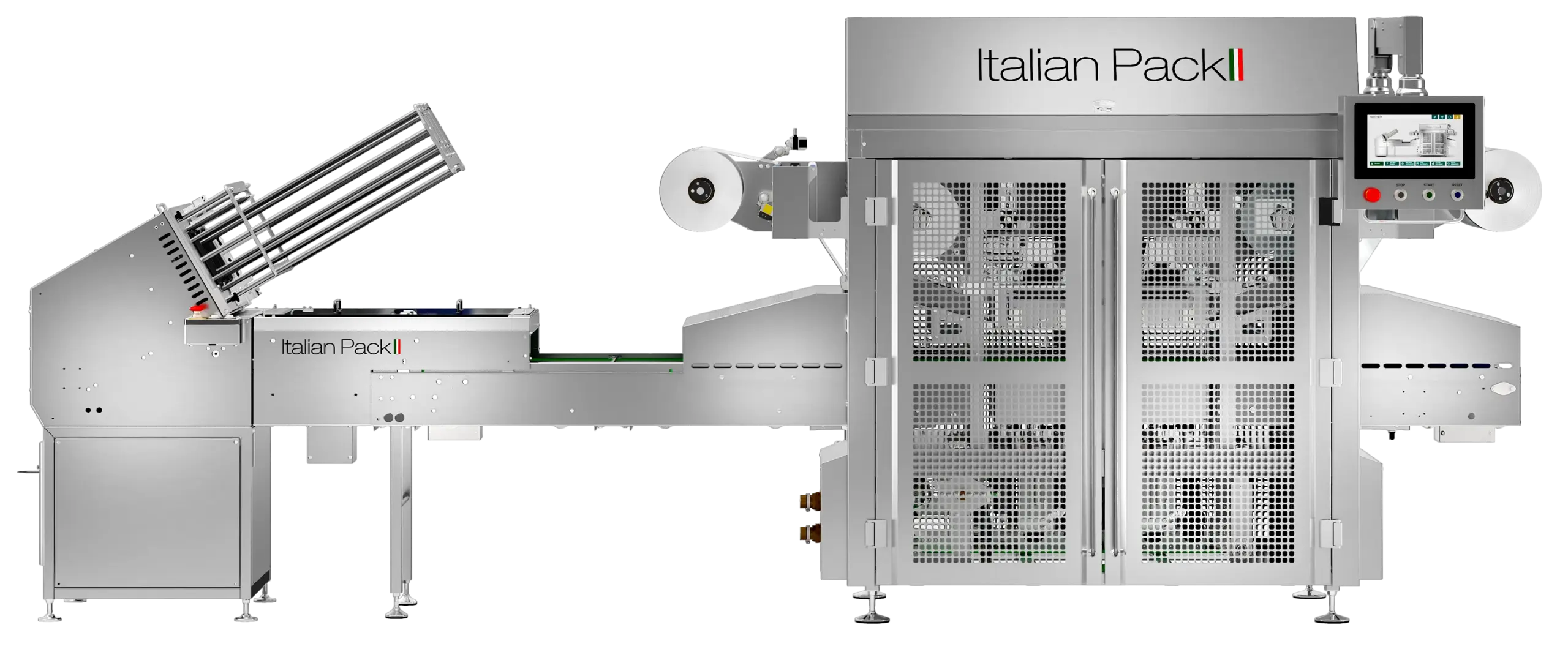

Denester

Tray denester with up to 6 lines. Quick format change available.

Optional Gas Buffer Tank

Stainless steel gas buffer tank with pressure regulator.

Teleservice

Remote teleservice by modem

Film printer

Predisposition for trays divider

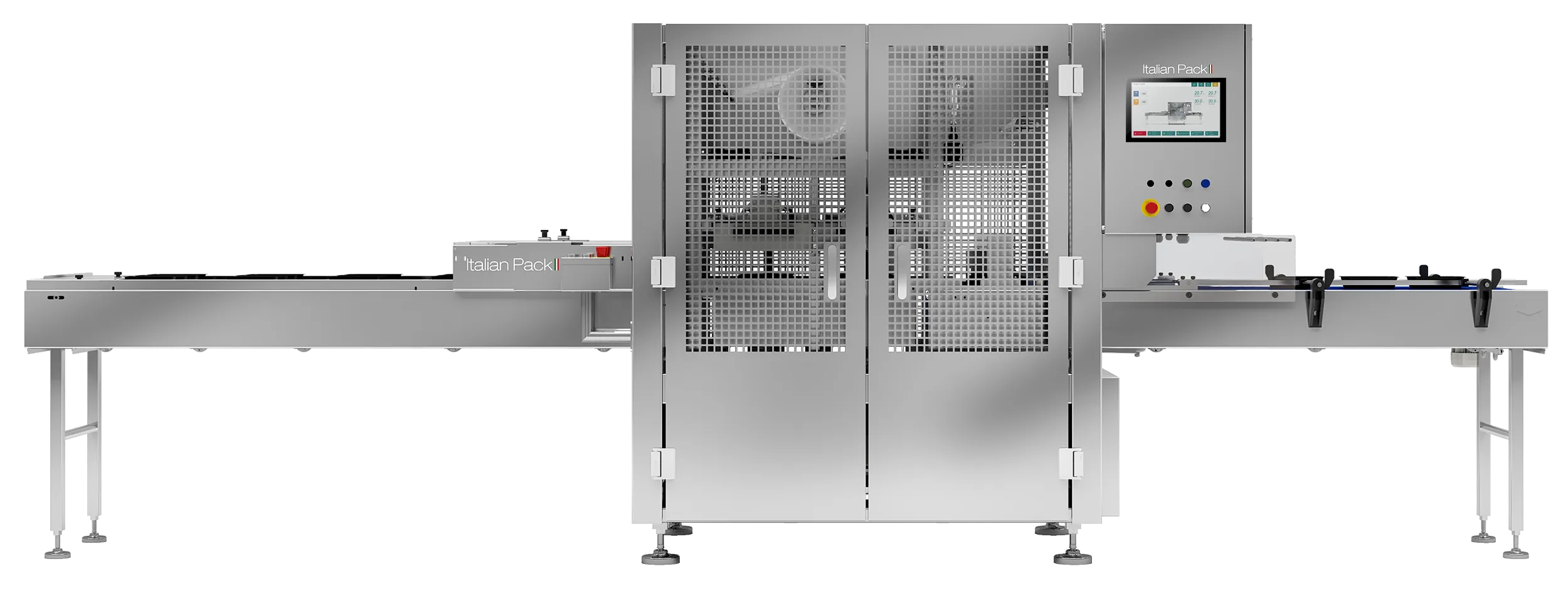

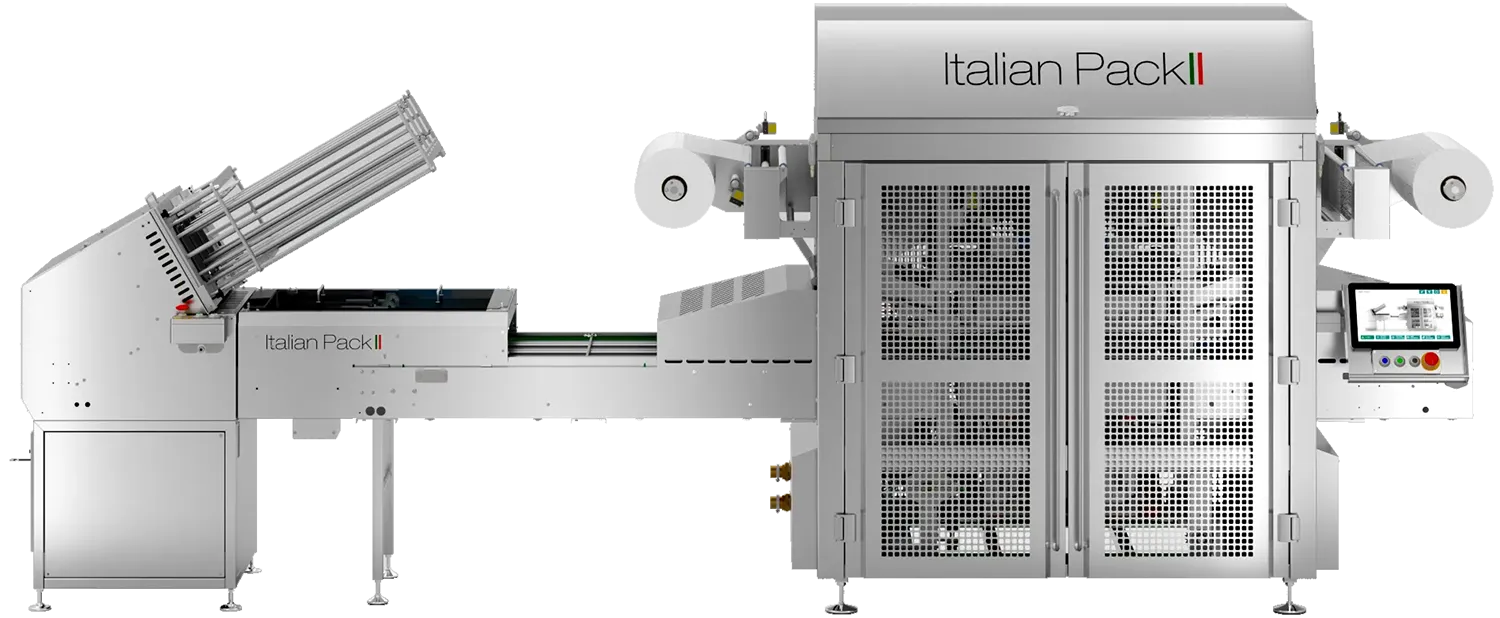

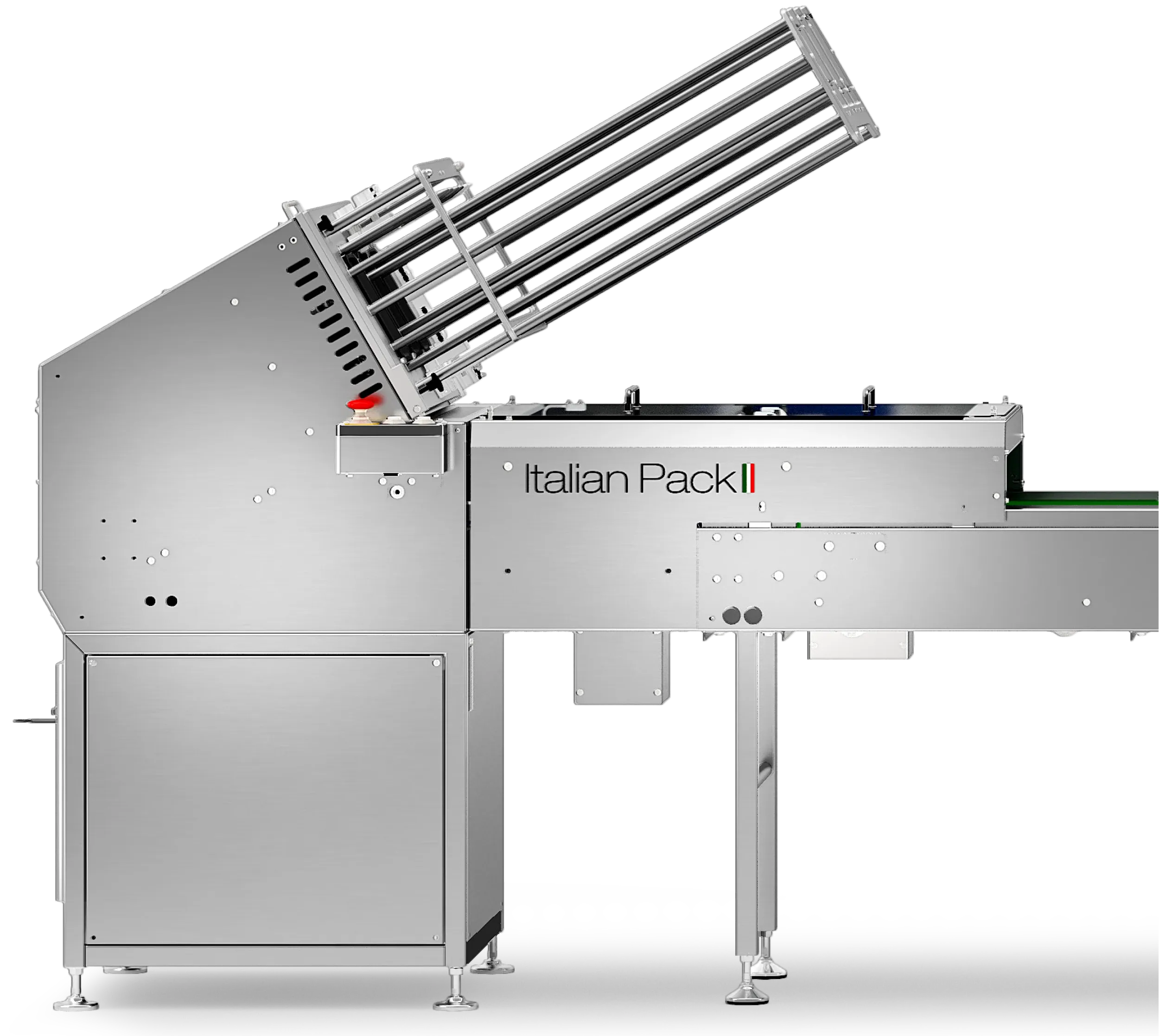

Polaris Twin xL

Eco Friendly

- Double film coil increase the autonomy during production. TIME SAVING

- The machine make the use of ultra-thin and ECO-SUSTAINABLE materials possible

- 1 tool, all the technologies: TOP SEAL (PACK), STRETCH, GAS FLUSH, VAC, MAP, SKIN, SKIN PROTRUDING, SKIN PROTRUDING FLATBOARD.

FLEXIBILITY - Small dimensions allow to integrate automatic systems even in reduced spaces. COMPACTNESS

- High speed packaging cycle. HIGH PRODUCTIVITY

Polaris Twin XL Features

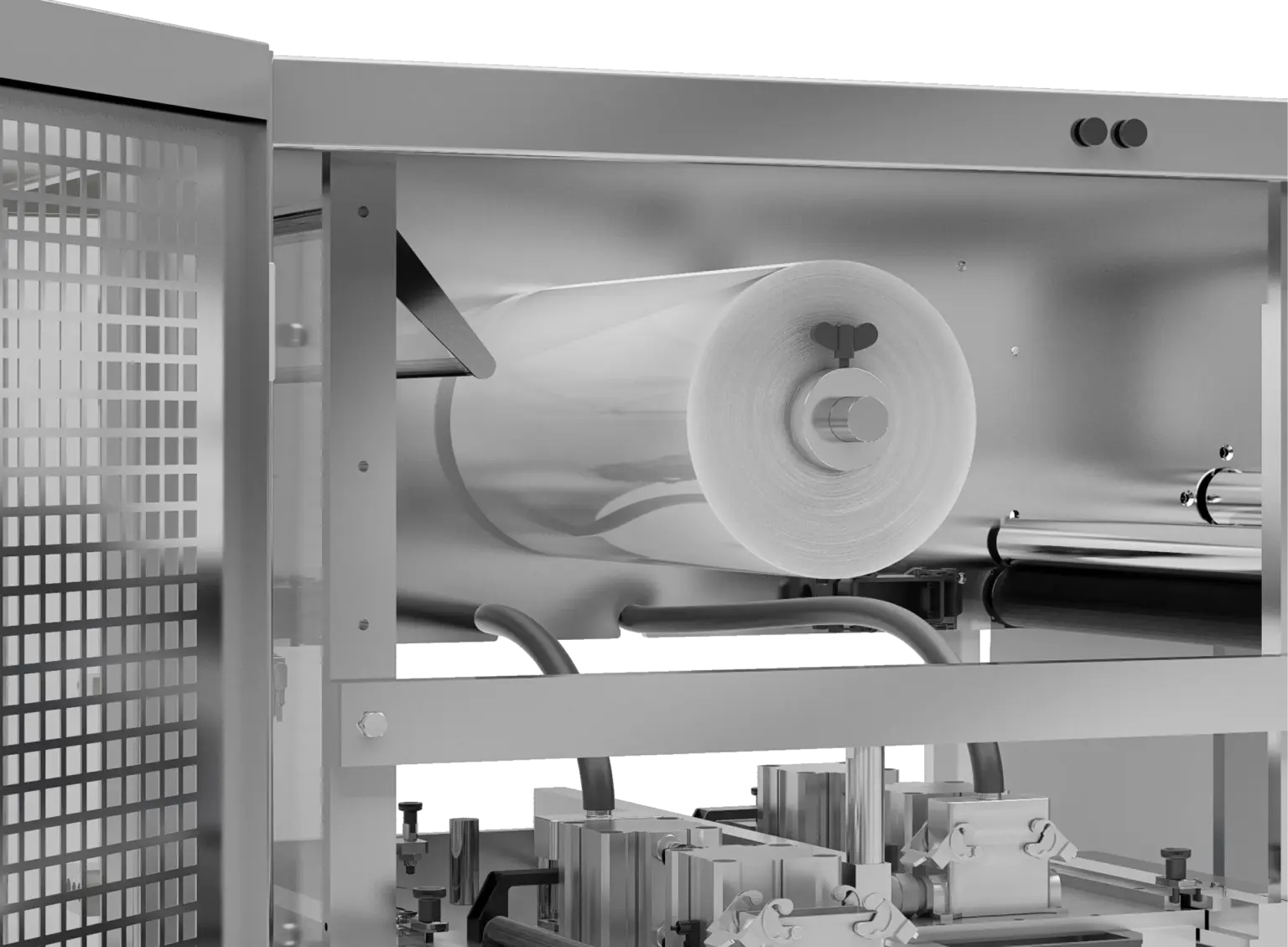

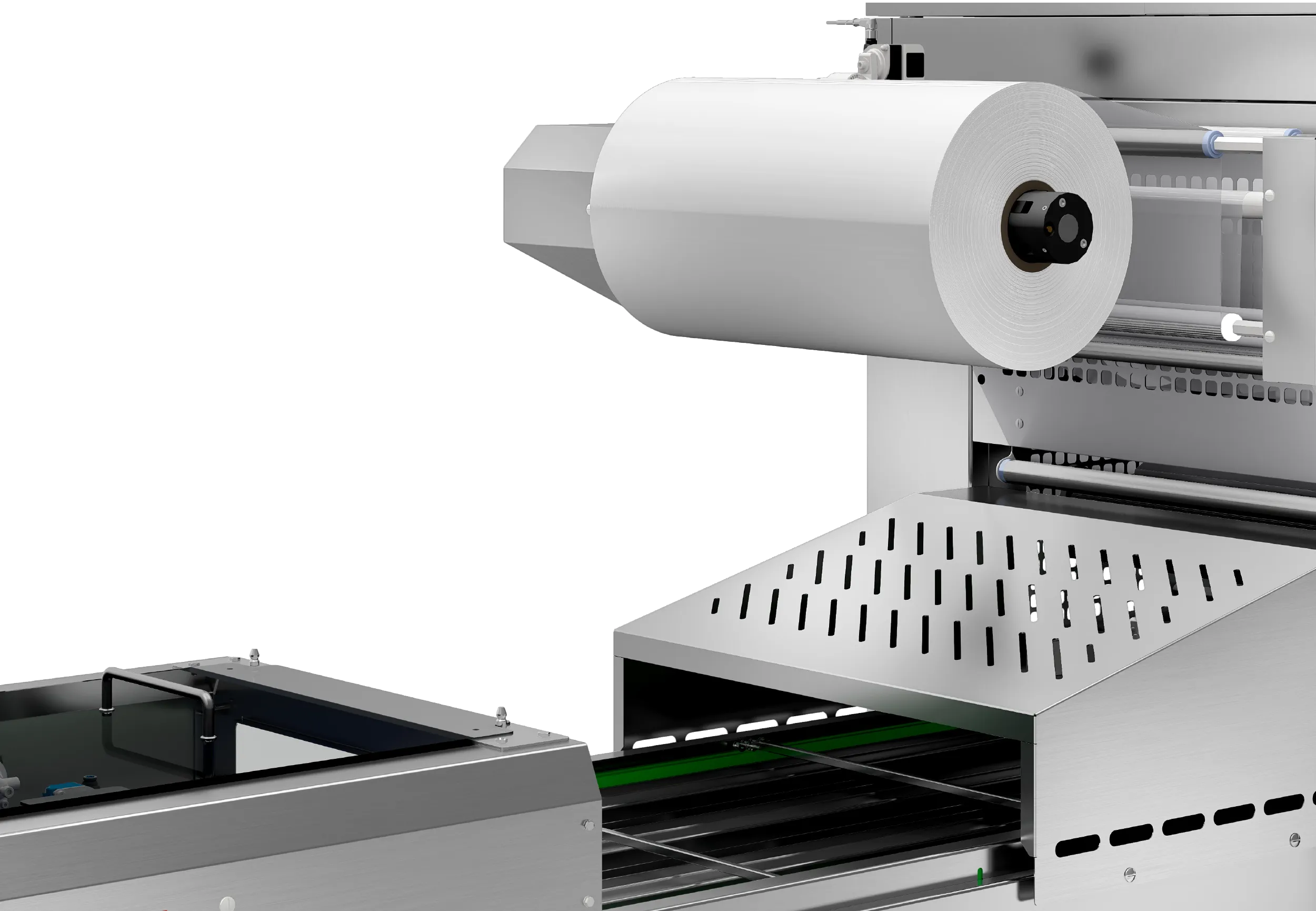

Double film coil shaft driven by brushles motor with expanding shaft

Double film waste rewinding by brushless motor with expanding shaft

Denester

Denester for Flat paper board and trays